Plastic Injection Molding Equipment If you utilize a plastic shot molding device as part of your production operation, it’s critical to seek details points. Besides, you anticipate a great deal from the equipment. Therefore, it needs to do ideally. For…

When it concerns production, several firms rely upon numerous services yet have little knowledge about the procedures themselves. Take the stretch blow molding machine as a best instance. Although various sectors depend on it to generate finished products based on…

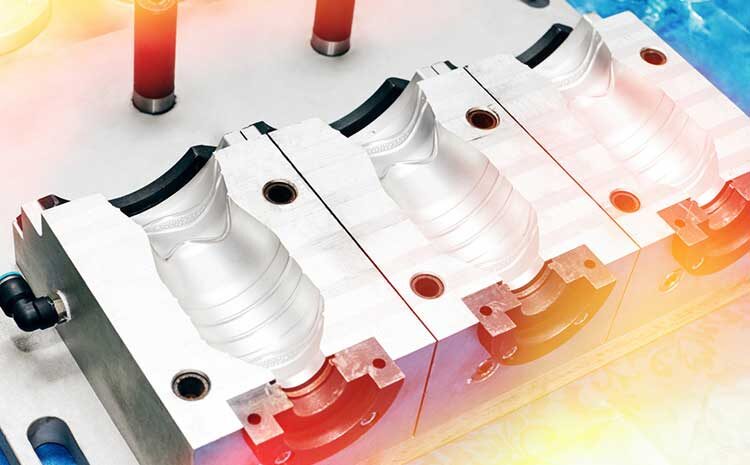

For making plastic bottles, specialists rely on a cutting edge blow molding maker. With this certain procedure, a supplier creates a broad range of finished items in differing shapes and sizes. Because of that, multiple markets depend upon a professional…

Extrusion Impact Moulding Machine When it involves competition, the manufacturing sector deals with some of the fiercest. Not only is this sector diverse but for you to preserve as well as boost consumers, it’s critical that you offer accuracy products.…

Blow molding machine As with any devices, failures occasionally take place when working on a blow molding device. Not only is this irritating, but otherwise corrected promptly, it can bring about expensive downtime. Actually, duplicated failings could cause business to…

The upside down head is the first of 4 kinds of injection blow molding machines. With all the hydraulics resting below the mold at the base of the equipment, this is by far among one of the most preferred options.…

If you use a plastic shot molding device as part of your manufacturing procedure, it’s essential to search for particular things. After all, you expect a lot from the equipment. For that reason, it requires to perform ideally. For effectiveness…

When it pertains to manufacturing, numerous companies rely upon different solutions yet have little expertise about the processes themselves. Take the stretch impact molding equipment as a best example. Although various markets depend on it to generate end products based…

For producing plastic containers, professionals rely upon a modern strike molding machine. With this specific procedure, a maker produces a wide series of completed items in differing shapes and sizes. As a result of that, several ind ustries rely on…

Drinks can be easily integrated and geared towards people in an active lifestyle. Carbonated drinks are at the top list for soft drinks. It gives a creative taste experience and is based on natural ingredients. Customers prefer PET juice bottles…