Glue Labelling Machine - A Detailed Report

- Introduction

In the bustling aisles of supermarkets, amidst the colorful array of online product listings, or even at the quiet corners of boutique stores, the first touchpoint between consumers and products is often the label. Historically, labels have been simplistic – a plain identifier to distinguish one item from another. However, in today’s complex and competitive marketplace, labelling has transformed and evolved, not only serving as an identifier but as an emblem of trust, a storyteller, and a crucial component of branding and compliance. At the heart of this dynamic evolution stands the sophisticated machinery responsible for precise and effective labelling – the Glue Labelling Machine. This introduction seeks to illuminate the vital role of this machine, its importance in contemporary product packaging, and the nuanced layers of its impact on branding and consumer perception.

In an era where consumer awareness is at its zenith, the quest for transparent, clear, and detailed product information has become paramount. Consumers no longer just glance at the brand name; they delve deep, reading the ingredients, understanding the origins, examining certifications, and more. This paradigm shift underlines the escalated significance of labelling. It’s not just about sticking a name on a product anymore; it’s about building trust, offering transparency, and cultivating brand loyalty.

Branding, in its essence, is the art and science of creating a recognizable and trustworthy space for a product in a consumer’s mind. The label, being the most tangible and direct touchpoint, plays an instrumental role in this. Think about any iconic brand, and one can almost visualize its label. This instant recall underscores the power of effective labelling. It’s not just a medium to relay information but a canvas where brand stories unfold, values are showcased, and promises are made.

In tandem with branding is the critical aspect of compliance. With stringent regulations and standards in place across industries, especially in sectors like food & beverages, pharmaceuticals, and cosmetics, labels are often the testament to a product’s adherence to these norms. Nutritional facts, allergen information, usage guidelines, side effects, certifications – all these and more find a place on labels, ensuring consumers are well-informed and products meet industry standards.

However, achieving this intricate balance between branding and compliance is no small feat. It requires precision, consistency, and efficiency – attributes synonymous with the Glue Labelling Machine. While the name might sound simple, the machinery is a marvel of modern engineering. It’s not just about sticking a label on a product; it’s about ensuring it’s perfectly aligned, the adhesive is uniformly applied, there’s no air bubbles or creases, and the label can withstand various conditions like temperature changes, humidity, and more.

But why glue? In the vast spectrum of adhesives, glue stands out for its versatility, bond strength, and adaptability. The Glue Labelling Machine harnesses these properties, ensuring labels not only stick but stay put, irrespective of external challenges. The bond formed is not just physical but metaphorical, representing the bond between brands and their consumers, built on trust, transparency, and consistency.

As we delve deeper into the world of labelling, it’s evident that the Glue Labelling Machine is not just a tool but a catalyst. It catalyzes brand growth, consumer trust, and industry compliance. In a world where choices are abundant, and attention spans are fleeting, this machine ensures that when a consumer picks up a product, the label speaks volumes, resonating with the brand’s essence, its promise, and its commitment to quality and integrity.

- Overview of the Glue Labelling Machine

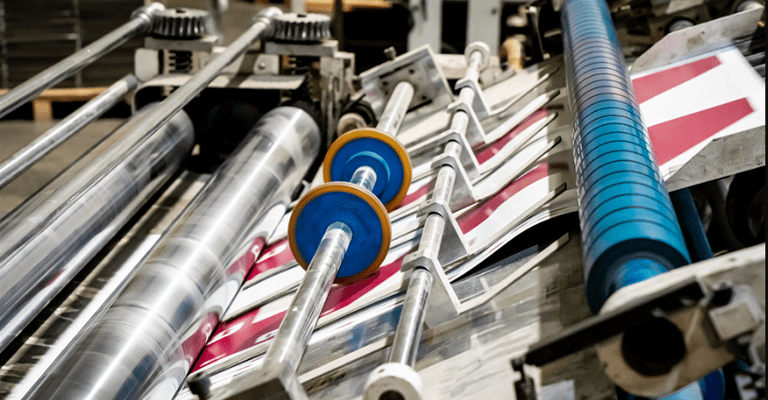

The core of a Glue Labelling Machine is its ability to seamlessly synchronize the processes of fetching a label, applying adhesive, and placing it onto a product. As products move on a conveyor, the machine takes labels, systematically applies glue, and affixes them onto containers, ensuring optimal adhesion and placement.

The machine’s efficiency stems from its sophisticated mechanism, ensuring labels are perfectly aligned, wrinkle-free, and securely bonded to the product, regardless of its shape or material.

- Key Features of a Glue Labelling Machine

Versatility: One of the standout features of the Glue Labelling Machine is its sheer adaptability. In a diverse market with a multitude of products varying in shapes, sizes, and container materials, a one-size-fits-all approach is obsolete. This machine, ingeniously designed, can accommodate an expansive range of product containers. Whether you’re dealing with slender vials, rotund jars, square containers, or even irregularly shaped novelty items, the machine is adept at ensuring labels are applied seamlessly. Such versatility ensures that manufacturers aren’t restricted by the capabilities of their machinery and can freely innovate in product design without worrying about labelling constraints.

Precision: The age-old adage, “accuracy is key,” couldn’t be more relevant in the realm of product labelling. Imperfectly placed labels can be detrimental, leading to a misinformed customer or even compliance issues. The Glue Labelling Machine is equipped with state-of-the-art sensors and advanced control mechanisms. These intricate systems ensure that each label, regardless of its size or design, is positioned impeccably on the product. There’s no room for overlaps, bubbles, or misalignments; every label is a testament to precision, reaffirming the brand’s commitment to excellence.

Speed: In today’s fast-paced manufacturing environment, speed is synonymous with efficiency. Delays in any segment of the production line can lead to cascading setbacks. Recognizing this, the Glue Labelling Machine is calibrated for high-velocity operations. It doesn’t just apply labels; it does so at a pace that ensures production lines are fluid, dynamic, and uninterrupted. This rapid application doesn’t compromise on quality, striking a perfect balance between speed and precision.

Durability: Industrial machinery is an investment, and longevity is a critical determinant of its value. The Glue Labelling Machine, crafted with high-grade materials and precision engineering, promises durability. It’s not just about withstanding daily operations but doing so over extended periods without significant wear and tear. This durability ensures consistent performance, minimal downtime, and a high return on investment.

- Advantages of Using a Glue Labelling Machine

Cost-Efficient: In the grand scheme of manufacturing, operational costs can quickly accumulate, eating into profit margins. Manual labelling, apart from being labor-intensive, is also rife with inconsistencies and inefficiencies. The Glue Labelling Machine, with its automated processes, significantly curtails these inefficiencies. The reduced need for manual labor, combined with the machine’s speed and precision, leads to tangible cost savings. When extrapolated over large production volumes, the savings are substantial.

Consistent Quality: Branding hinges on consistency. A brand that offers consistent quality assures its customers of its reliability. The Glue Labelling Machine, with its meticulous design and advanced controls, ensures that every label it applies echoes the same high standard. There’s no variance, no outliers, just a steady stream of perfectly labelled products, each one mirroring the brand’s commitment to quality.

Flexibility: The adhesive world is vast, with various types catering to specific needs. While some products might benefit from water-based adhesives due to their eco-friendliness and easy clean-up, others might require the robust bond of hot melt adhesives. The Glue Labelling Machine’s design accommodates this diversity, capable of handling both adhesive types. This adaptability ensures manufacturers aren’t bound by the machine’s limitations and can choose the adhesive that aligns with their product’s needs and brand ethos.

Reduced Waste: In our increasingly eco-conscious world, waste reduction is not just an operational advantage but an environmental responsibility. One of the unsung benefits of the Glue Labelling Machine is its precision in adhesive application. It calculates, based on the label size and material, the exact amount of glue required, ensuring there’s no excess. This precision leads to minimal adhesive waste, translating to cost savings and a reduced environmental footprint.

- Dunamis Machines: Elevating the Glue Labelling Experience

In the labyrinth of industrial machinery manufacturers, Dunamis Machines has etched a distinctive identity, revered not only for the caliber of its machines but for the holistic experience it offers its clients. When it comes to Glue Labelling Machines, Dunamis Machines has consistently showcased innovations that underscore its commitment to excellence, efficiency, and customer satisfaction.

Innovative Design: In a rapidly evolving technological landscape, obsolescence is a real threat. Dunamis Machines, with its finger on the pulse of emerging technologies, ensures its Glue Labelling Machines are always a step ahead. Incorporating cutting-edge technology means machines are not just efficient, but intuitive, user-friendly, and compatible with a range of materials and adhesives. This commitment to innovation ensures clients always have machinery that’s at the zenith of modern engineering.

Customer Support: A machine’s purchase is the beginning of a relationship, not the culmination. Recognizing this, Dunamis Machines has invested extensively in cultivating a robust post-sales support ecosystem. From addressing minor teething issues to offering comprehensive training sessions, their team ensures that clients can harness the full potential of their machine. Additionally, with a dedicated technical support team, any troubleshooting needs are addressed promptly, ensuring minimal operational downtime.

Custom Solutions: The diversity in the product landscape means that a one-size-fits-all approach is often inadequate. Dunamis Machines rises to this challenge, offering tailor-made solutions that cater to unique client needs and industry nuances. Whether it’s adapting to a new container shape, integrating with existing production lines, or catering to specific adhesive requirements, Dunamis ensures that their Glue Labelling Machines are not just fit for purpose but optimized for individual operational landscapes.

Sustainability: The environmental impact of industrial operations is under the microscope, and Dunamis Machines is leading the charge towards greener solutions. Their Glue Labelling Machines are crafted to be energy-efficient, consuming minimal power without compromising on performance. This dual advantage ensures reduced operational costs and a smaller carbon footprint, making it a win-win for businesses and the planet.

- Application Industries: The Diverse Landscape of Glue Labelling

The versatility of the Glue Labelling Machine, especially those crafted by Dunamis Machines, is evident in its wide applicability across diverse industry sectors. Each sector, with its unique requirements and challenges, finds a reliable partner in these machines.

Food & Beverage: In an industry where freshness is paramount, labels often relay crucial information like manufacturing dates, ingredients, nutritional facts, and more. Whether it’s the curvaceous contours of a wine bottle, the robust facade of a jam jar, or the sleek profile of an energy drink can, Dunamis Machines’ Glue Labelling solutions ensure labels adhere perfectly, enhancing product appeal and ensuring compliance.

Pharmaceuticals: Trust is the cornerstone of the pharmaceutical industry. Patients rely on labels for dosage information, side effects, manufacturing details, and more. From small vials that house critical vaccines to larger bottles of over-the-counter medications or tubes of ointments, the precision and reliability of Dunamis Machines’ Glue Labelling ensure that every label conveys trust and authenticity.

Cosmetics: In the world of cosmetics, packaging is as vital as the product itself. It’s about creating a brand aura, an appeal. Perfume bottles, with their intricate designs, lotion containers, with their ergonomic shapes, or even lipstick tubes, all rely on labels to enhance their aesthetic appeal and relay product information. Dunamis Machines, with its precision engineering, ensures that every label enhances the product’s allure.

Chemicals: Safety is paramount in the chemical industry. Labels here often relay critical safety information, usage guidelines, and more. Whether it’s a bottle of household cleaning agent, an industrial solvent can, or even a container of automotive fluids, the Glue Labelling Machines from Dunamis ensure labels are affixed securely, resistant to the often aggressive chemicals they’re paired with.

- Challenges & Solutions: Navigating the Complex Landscape of Glue Labelling

The revolutionary impact of Glue Labelling Machines in the packaging and manufacturing sector is undeniable. However, as with any technology, the journey of these machines isn’t devoid of challenges. Recognizing and addressing these hurdles is critical to harness the full potential of this machinery.

Adhesive Issues: Adhesives, the bedrock of labelling, can be temperamental. Depending on geographical locations and associated climatic conditions, they can manifest varied behaviors. In colder climates, certain adhesives might harden, making them difficult to apply uniformly. Conversely, in hotter regions, they might become overly viscous or runny, leading to uneven application or potential drips.

Solution: Dunamis Machines, with its extensive research and development initiatives, has engineered machines that aren’t just adaptable but also intuitive. Recognizing the adhesive’s consistency, these machines adjust their application techniques, ensuring optimal results. Moreover, they are compatible with a wide spectrum of adhesive types, each tailored for specific climatic conditions. This adaptability means whether you’re operating in the frosty climes of Scandinavia or the tropical warmth of Southeast Asia, the machines deliver consistent, high-quality labelling.

Label Positioning: In the world of branding, every millimeter counts. A label placed even slightly askew can adversely impact the product’s visual appeal, potentially undermining brand perception. Moreover, inaccurate placement can lead to regulatory non-compliance, especially in industries where label information is mandated by law.

Solution: Precision is at the core of Dunamis Machines’ ethos. Their Glue Labelling Machines are equipped with cutting-edge sensors that detect the product’s contours, dimensions, and orientation. Complementing these sensors are advanced calibration tools that adjust the machine’s operations in real-time, ensuring impeccable label positioning. With such meticulous engineering, every label applied is a testament to perfection, enhancing brand reputation and ensuring regulatory compliance.

- The Future: Charting the Path of Innovations in Glue Labelling

The technological zeitgeist is dynamic, with innovations emerging at an unprecedented pace. The realm of glue labelling is not immune to these advancements, and as we gaze into the future, several transformative trends loom on the horizon.

Integration with IoT: The Internet of Things (IoT) is reshaping industries, bringing interconnectivity and real-time data exchange to the forefront. In the context of Glue Labelling Machines, IoT integration promises a future where machines are perpetually connected, communicating vital data in real-time. This data-driven approach can optimize the labelling process, predicting potential adhesive issues, auto-adjusting to varying product batches, and even scheduling maintenance activities before issues arise.

Eco-friendly Machines: As global consciousness shifts towards sustainability, the demand for eco-friendly machinery is escalating. The future will see Glue Labelling Machines that are not only energy-efficient but also designed to minimize waste. These machines would optimize adhesive usage, reduce power consumption, and potentially integrate with renewable energy sources.

AI-driven Operations: Artificial Intelligence (AI) is no longer the stuff of science fiction; it’s a tangible force driving industrial innovations. Glue Labelling Machines of the future will harness AI to auto-adjust operations based on the product type, label design, adhesive consistency, and more. Imagine a machine that learns from every label it applies, continuously refining its operations, reducing manual interventions, and guaranteeing unparalleled consistency and quality.

At the vanguard of these innovations stands Dunamis Machines. With a legacy of engineering excellence and a vision anchored in future-readiness, they are poised to redefine the contours of glue labelling. Their commitment to research and development, coupled with their unwavering focus on customer-centric solutions, ensures that clients are always equipped with best-in-class machinery, capable of navigating the challenges of today and capitalizing on the opportunities of tomorrow.

Crafting a detailed conclusion that encapsulates the intricate dynamics, challenges, and prospective future of the Glue Labelling Machine, with particular emphasis on the exemplary contributions and solutions provided by Dunamis Machines, requires a careful weaving of past insights, present challenges, and future predictions.