The Future of Beverage Packaging: Predictions and Innovations

Since the beginning, shifting consumer preferences, technological advancements, and material availability have all had a significant impact on the evolution of beverage packaging. Future developments in the beverage packaging industry are anticipated to be profound, with a focus on innovation, environmental responsibility, and meeting changing consumer demands. In this deep evaluation, we will look at the predictions and potential innovations that are shaping the future of beverage packaging. Influenced by a combination of customer demand, technical breakthroughs, and environmental conscience, the future of beverage packaging promises to be inventive and sustainable.

Eco-Friendly Resources

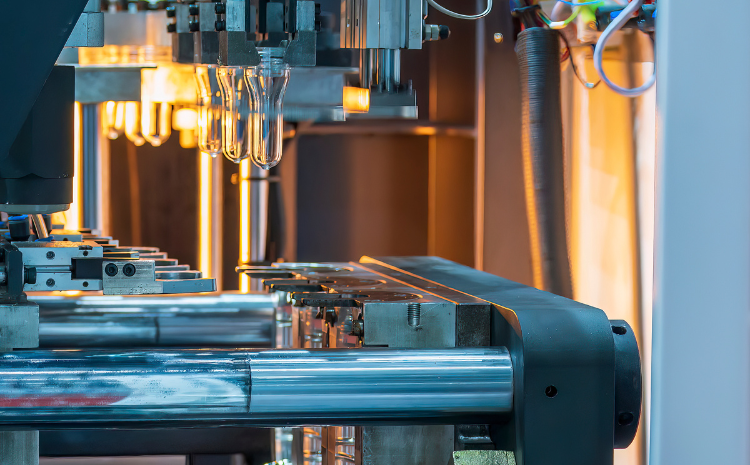

The move towards sustainable materials is one of the major trends influencing beverage packaging in the future. Dunamis Machinies are facing pressure to implement environmentally sustainable packaging options due to growing concerns about plastic pollution and environmental damage. This covers the use of plant-based materials like PLA (polylactic acid), biodegradable plastics, and creative substitutes like edible packaging made of seaweed or other natural ingredients.

Dunamis Machinies can lessen their environmental impact and attract eco-aware customers by adopting sustainable materials. The emergence of bioplastics, which come from renewable resources like plant starches, agricultural by products, or even algae, is one of the most exciting trends in this field. By providing a sustainable and biodegradable substitute for plastics derived from petroleum, these materials aid in lowering dependency on fossil fuels and lessening their negative effects on the environment.

Smart Packaging

The integration of technology into beverage packaging, or “smart packaging,” is another notable development that will shape the future. Improved traceability, engaging consumer experiences, and greater product safety are just a few benefits of smart packaging. NFC (Near Field Communication), RFID (Radio Frequency Identification), and QR codes are some of the technologies that enable it. For example, RFID tags allow products to be tracked throughout the supply chain, and QR codes allow customers to learn about the contents, nutritional value, and origin of a product. As technology advances, we should expect to see even more inventive use of smart packaging in the beverage industry. Product safety, traceability, and consumer interaction will all benefit from smart packaging.

Reusable Containers

Numerous beverage businesses are investigating reusable packaging alternatives in response to growing concerns around single-use plastics. Refillable bottles, kegs and other reusable containers that can be cleaned, returned and filled again fall under this category. Beverage firms may offer consumers a more sustainable option to single-use packaging while also drastically reducing waste and environmental impact by implementing reusable packaging.

Within the realm of bottle packaging, reusable containers encompass refillable bottles composed of sturdy materials like glass or premium plastics, in addition to additional reusable packaging styles like growlers or kegs. It takes considerable thought and preparation to use reusable packaging for bottle packing. The following are essential actions that beverage firms should take to implement reusable packaging with success:

- Material Selection:For reusable packaging, choose for strong, long-lasting materials like glass, stainless steel, or premium plastics. When choosing materials, take durability, recyclable nature, and simplicity of cleaning into account.

- Design Elements to Remember:Create packaging designs or reusable bottles that are both aesthetically beautiful and practical. When creating reusable packaging, take into account elements like brand identity, ergonomics, and ease of use.

- Distribution and Logistics: Create a procedure for gathering, sanitising, and restocking reusable containers or bottles. This may involve putting in place a reverse logistics system to move empty containers back to a central facility for cleaning and refilling, or it could entail creating collecting stations at retail sites.

- Partnerships and Cooperation:To encourage and support the use of reusable packaging, cooperate with distributors, retailers, and other stakeholders. Refill stations and incentives for returning empty bottles can be offered in conjunction with merchants to boost customer participation and adoption of reusable packaging choices.

Design Minimalism

The trend of minimalist packaging design is growing in popularity as people look for clarity and simplicity when making purchases. Clean, simple designs that put environment and use ahead of extravagant branding and packaging are characteristics of minimalist packaging. Beverage firms can cut expenses and attract eco-aware customers who seek out items with little environmental impact by simplifying packaging designs and eliminating superfluous materials.

Bottle packaging ideas can be quickly prototyped and tested for suitability by using 3D printing technology. Before going into mass production, packaging designers can assess shape, fit, and usefulness by constructing physical models of their ideas. Additionally, complex and personalised package designs that would be difficult or impossible to build using conventional manufacturing techniques may now be created thanks to 3D printing.

Bottle package design has more possibilities and flexibility thanks to digital printing technology. Digital printing makes it possible to print different designs, colours, and graphics directly onto packaging materials on demand, in contrast to traditional printing techniques that have large setup costs and call for printing plates. This makes it possible for firms to build distinctive, eye-catching packaging that stands out on store shelves.

Innovative methods are being investigated by designers to produce biodegradable bottle packaging solutions out of sustainable materials like paperboard, natural fibres, or bioplastics. Through the use of biodegradable materials into packaging designs, designers may create environmentally friendly solutions that lessen pollution and support the circular economy. Designing biodegradable packaging also entails taking end-of-life situations into account and making sure that the materials used can break down effectively and securely in a variety of settings.

Nanotechnology

Nanotechnology has the potential to completely transform the bottle packaging industry by providing creative answers to problems that arise in the field and enhancing performance and functionality. With the use of nanotechnology, packaging materials with improved barrier qualities can now be created that effectively block gases, including moisture and oxygen, from escaping or seeping into bottles. Bottle packaging can retain the freshness, flavour, and quality of beverages for a longer time by adding nanoparticles or nanocomposites to materials like plastic, glass, or coatings.

By the application of nanotechnology, bottle packaging printing and labelling processes can now incorporate holographic effects, anti-counterfeiting features, and high-resolution images. Vibrant colours, improved adherence, and resistance to fading and smudging are provided by nanoparticle-based inks and pigments, guaranteeing that packaging designs stay aesthetically pleasing and readable for the duration of the product lifecycle. Additionally, to improve trademark protection and authenticity, nanomaterials with particular optical properties, such plasmonic nanoparticles, can be utilised to construct security features or hidden codes that are undetectable to the unaided eye but identifiable with specialised equipment.

Bottle packaging solutions that are flexible and lightweight can be developed by using nanotechnology, which also lowers the environmental effect and material consumption. The mechanical qualities of packing materials can be improved by nanocomposites made of nanoparticles scattered throughout polymer matrices, enabling the creation of lighter, thinner structures without compromising their strength or durability. Furthermore, adaptable barrier coverings or pouches that fit the shape of bottles can be made using nanofibers or nanolaminates, providing effective packaging solutions for a variety of beverage goods.

A wide range of creative ways to boost performance, solve sustainability issues, and increase functionality are provided by the incorporation of nanotechnology into bottle packaging for the beverage sector. Bottle packaging may become smarter, safer, and more ecologically friendly by using nanomaterials, nanocoatings, nanosensors, and other nanotechnologies, satisfying the changing demands and expectations of both consumers and companies.

Biodegradable Packaging

As an environmentally friendly substitute for standard plastics, which can take hundreds of years to break down, biodegradable packaging materials are available. When a material reaches the end of its useful life, it can be recycled or composted since biodegradable materials break down more quickly, such as bio-based plastics, compostable polymers, and natural fibres. Beverage firms can lessen their environmental impact and help the worldwide fight to combat plastic waste by adopting biodegradable packaging. The beverage industry is moving towards a more sustainable future because to predictions and advancements in biodegradable bottle manufacturing.

Active packaging technologies will be included into biodegradable bottle packaging in the future to improve product safety and shelf life. In order to suppress microbial growth, stop oxidation, and preserve product freshness, researchers are investigating the integration of natural antimicrobial agents, antioxidants, and oxygen scavengers into biodegradable materials. The quality and safety of bottled beverages are guaranteed by these active biodegradable packaging options, which provide environmentally friendly substitutes for traditional plastic bottles.

Developments in biodegradable coatings will make it possible to create practical and adaptable bottle packaging options. Biopolymer bottles can be made more durable, moisture resistant, and printable by applying biodegradable coatings made of natural materials like shellac, beeswax, or plant-based resins. Functional coatings that contain oxygen scavengers or antimicrobial agents can also enhance protection and increase the shelf life of bottled beverages.

It is expected that advancements in biodegradable barrier coverings in the future will enable the broader adoption of biodegradable bottle packaging for alcoholic and carbonated drinks, as well as juices. To ensure that bottled beverages stay fresh and preserve their carbonation, researchers are developing biodegradable barrier films with superior gas barrier properties, such as oxygen and CO2 permeability. Upon reaching the end of their useful lives, these biodegradable barrier films can be recycled or broken down into compost, offering a sustainable option to petroleum-based plastics.

In the future, Dunamis Machines will be able to customise biodegradable packaging materials to achieve particular sustainability objectives and performance standards. The mechanical characteristics, rates of biodegradation, and recyclable nature of biopolymer bottles are expected to be improved by the use of biodegradable additives, such as natural fibres, starches, or enzymes. Beverage firms may design unique and environmentally-friendly bottle packaging solutions that are consistent with their brand values and consumer preferences by introducing customisable biodegradable additives into their packaging compositions.

Among the advancements in biodegradable packaging will be improvements in supply chain transparency and traceability to ensure the authenticity and sustainability of biodegradable materials. Predictions state that blockchain technology will be incorporated into biodegradable packaging solutions to allow for real-time tracking and traceability of materials from point of origin to end of life. Through the use of blockchain technology, beverage companies may enhance consumer confidence and transparency by confirming the environmental credentials, production methods, and provenance of biodegradable packaging materials.

Initiatives aimed at educating and involving consumers will be used in the future of biodegradable bottle packaging to promote the advantages and safe disposal practices of biodegradable materials. Dunamis Machines will educate consumers about the environmental effect of conventional plastics and the benefits of transitioning to biodegradable packaging solutions through marketing campaigns, labelling, and instructional materials. Beverage firms can promote the use of biodegradable bottle packaging in the market by arming consumers with information and promoting sustainable practices.

Packaging developments for biodegradable bottles will be aided by policies and incentives that promote the use of sustainable packaging. It is anticipated that governments will implement policies such as tax rebates, eco-labeling requirements, and extended producer responsibility (EPR) initiatives to encourage beverage companies to invest in biodegradable packaging technology. By providing incentives and regulatory support, policymakers could accelerate the transition to a more sustainable and circular economy, where biodegradable bottle packaging is crucial to reducing plastic pollution and slowing down climate change.

The beverage industry’s adoption of sustainable packaging solutions is being driven by advancements in materials, technology, and regulatory frameworks. This is encouraging news for the future of biodegradable bottle packaging. Using advances in biopolymer formulations, nanotechnology integration, active packaging systems, and supply chain transparency, Dunamis Machines can provide innovative and environmentally responsible bottle packaging solutions that meet the needs of consumers, brands, and the environment.

Future developments in beverage packaging could include modular systems that provide customers with flexibility and variety. Customers can mix and match flavours, adjust serving sizes, and modify container designs using modular packaging solutions. Brands can reduce packaging waste and accommodate a wide range of consumer preferences by providing modular packaging alternatives.

Advances in data analytics and consumer insights will impact future innovations in beverage package design. Companies will develop package solutions that appeal to target customers and meet shifting customer wants by utilising consumer data, market trends, and feedback. With data-driven packaging design, brands can create packaging that is both functional and aesthetically pleasing, boosting customer satisfaction and brand loyalty.

Functionality and features that support health will be given priority in beverage packaging in the future to meet the changing needs of health-conscious consumers. It is anticipated that packaging will incorporate functional elements including built-in measuring cups, calorie control indicators, and resalable closures to enhance ease and use. Moreover, adding functional components to packaging materials—like probiotics, vitamins, or antioxidants—will enhance general wellbeing and offer further health benefits.

Temperature control in beverage packaging

One of the most important factors that directly affects the product’s quality, taste, and freshness in beverage packaging is temperature regulation. Beverage packaging uses contemporary insulating materials to control temperature. These parts can help regulate the container’s inner temperature so that the beverage is kept warm or cold as needed. Packaged beverages that are temperature-sensitive, including some types of wine, beer, or dairy goods, should be insulated.

Phase change materials are substances that, as they change from one phase to another, such as from a solid to a liquid or vice versa, have the capacity to both absorb and release thermal energy. To help maintain temperature, PCMs can be added to beverage containers. For example, PCM-based packaging may absorb excess heat to keep beverages chilled or may release stored energy to keep hot beverages like coffee or tea warm.

Temperature control is necessary to preserve beverage quality, but it’s also crucial to consider how packaging materials and technology may affect the environment. Future developments in temperature-controlled packaging should prioritise sustainability, utilising eco-friendly materials and energy-saving technologies whenever possible to lessen their environmental impact.

Temperature-controlled packaging techniques can be used to package beverages of all kinds, including dairy products, juices, alcoholic and non-alcoholic beverages. varied beverages have varied optimum temperatures, thus packaging solutions should be adaptable enough to accommodate these variations. There is room for innovation in the temperature regulation of beverage packaging, as there are possible uses for it in a variety of beverage kinds and consumer preferences. Future packaging solutions can guarantee that beverages are supplied to customers at the ideal temperature, increasing their enjoyment and satisfaction, by utilising cutting-edge materials, technologies, and design principles.

A realistic response to the problems with single-use plastics on the environment can be found in reusable bottle packaging. Through promoting container reuse rather than single-use container disposal, Dunamis Machines may lower waste, preserve resources, and foster customer loyalty. Reusable packaging has the power to completely change the beverage business for future generations if it is well planned and implemented.