Heat Shrink Wrap Machines for Bottles: How They Ensure Perfect Packaging

In the modern manufacturing and packaging industry, efficiency and reliability are paramount. Businesses across industries are constantly seeking ways to optimize their production lines while ensuring product safety, quality, and visual appeal. Among the most vital pieces of equipment for streamlining these processes are bottle shrink wrapping machines. These machines have become indispensable for industries ranging from beverages to cosmetics, offering a robust, cost-effective, and visually appealing packaging solution.

This comprehensive guide delves into the importance of bottle shrink wrapping machines for production lines. We’ll explore their features, benefits, different types, how they work, and how to select the right one for your business. Whether you’re in the business of packaging bottled water, carbonated drinks, or pharmaceutical products, understanding the role of these machines can give you an edge in achieving operational excellence.

What are Bottle Shrink Wrapping Machines?

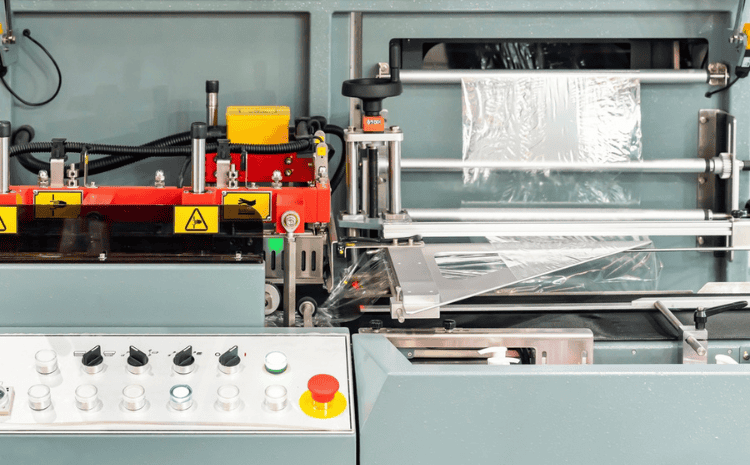

A bottle shrink wrapping machine is a type of packaging equipment specifically designed to wrap bottles in shrink film. Once wrapped, the bottles are passed through a shrink tunnel machine or subjected to heat, causing the film to shrink tightly around the bottle or bundle of bottles. This process creates a secure, protective seal that ensures the bottles are safeguarded during transportation, storage, and retail display.

These machines are equipped with automated or semi-automated systems that handle the wrapping, sealing, and heat-shrinking processes. This automation ensures precision, reduces labor costs, and provides consistent packaging quality. Variants such as automatic shrink wrap machines, heat shrink machines, and shrink wrapping systems cater to different production needs and output capacities.

Why Bottle Shrink Wrapping Machines Are Essential

- Enhanced Protection Against External Factors

Packaging is not just about aesthetics; it also protects the product from potential damage during storage or transportation. Bottle shrink wrapping machines wrap bottles in a layer of durable shrink film, which provides a barrier against dust, moisture, and other contaminants. This is particularly critical for industries like beverages, where maintaining the integrity of bottled products is crucial.

- Water bottle shrink wrapping machines ensure bottled water remains clean and intact, even in harsh storage or transit conditions.

- For fragile bottles, the shrink wrap acts as a cushioning layer that reduces the risk of breakage.

- Tamper-Evident Packaging for Consumer Safety

Tamper-evident packaging is a significant benefit of using bottle shrink wrapping machines. The tightly sealed shrink wrap provides a clear indication of whether a product has been tampered with, giving consumers confidence in the safety of the product. Industries such as pharmaceuticals and food & beverages rely heavily on tamper-evident packaging to comply with safety regulations.

- Automatic shrink wrap machines are designed to apply tamper-proof seals efficiently, meeting industry standards and protecting consumer trust.

- Professional Presentation for Improved Branding

Consumers are drawn to products that look well-packaged and professional. Bottle shrink wrapping machines ensure consistent, high-quality packaging that enhances the visual appeal of your product. Shrink wrap is transparent, allowing consumers to view the product while also protecting it. This is particularly beneficial for products with detailed labels or branding.

- Bundled bottles, such as six-packs of soda or water, benefit from a clean, organized presentation that enhances shelf appeal.

- Transparent shrink wrap highlights the label design, allowing your branding to shine through.

- Cost-Effective Packaging Solution

Although bottle shrink wrapping machines require an upfront investment, they are highly cost-effective in the long run. By automating the packaging process, businesses can reduce their reliance on manual labor and cut operational costs. Shrink wrapping eliminates the need for additional packaging materials, such as boxes or crates, while still providing a secure seal.

- Heat shrink wrap machines ensure minimal film wastage, optimizing material usage and further reducing costs.

- With faster production speeds, businesses can meet high-volume demands without increasing their workforce.

- Versatility Across Industries

Bottle shrink wrapping machines are used across a variety of industries, thanks to their ability to package bottles of different sizes, shapes, and materials. This versatility makes them a valuable asset for businesses in:

- Beverages: Packaging bottled water, soft drinks, and juices.

- Pharmaceuticals: Providing tamper-proof packaging for medicine bottles.

- Cosmetics: Ensuring the safe transport and storage of fragile or high-value cosmetic products.

- Food: Wrapping bottles containing sauces, syrups, and other liquid food items.

Key Features of Bottle Shrink Wrapping Machines

Modern bottle shrink wrapping machines are designed with advanced features to meet the demands of high-volume production lines. Some of these features include:

- High-Speed Performance

For large-scale operations, speed is critical. Automatic shrink wrapping machines are equipped to handle thousands of bottles per hour, ensuring businesses can meet production deadlines efficiently.

- Customizable Settings

These machines can be adjusted to accommodate different bottle sizes, shapes, and packaging configurations. Whether you’re wrapping individual bottles or bundles, the flexibility ensures seamless integration into your production line.

- Advanced Heating Systems

Shrink tunnel machines use precision-controlled heating elements to ensure even heat distribution. This guarantees consistent shrinkage and prevents damage to the product or label.

- Energy Efficiency

Energy-efficient designs reduce power consumption, lowering operational costs without compromising performance.

- User-Friendly Interfaces

Modern shrink wrapping machines feature intuitive touchscreens and automated diagnostics, making them easy to operate and maintain.

Types of Bottle Shrink Wrapping Machines

Bottle shrink wrapping machines come in various types to cater to different production capacities and operational needs. Understanding these types is crucial for selecting the right equipment for your business. Below is an in-depth look at the four primary types of bottle shrink wrapping machines:

- Manual Shrink Wrapping Machines

Manual shrink wrapping machines are the simplest form of shrink wrapping equipment, designed for small-scale operations or businesses with limited production requirements. These machines require significant manual intervention for placing bottles, applying shrink film, and sometimes operating the heating element.

Key Features:

- Cost-Effective: These machines are affordable and ideal for startups or businesses operating on tight budgets.

- Portability: They are compact and lightweight, making them easy to move and operate in limited spaces.

- Flexibility: Suitable for wrapping different bottle sizes and shapes, albeit at a slower pace compared to automated systems.

Applications:

- Small beverage manufacturers.

- Local cosmetic producers.

- Small-scale food bottlers.

Challenges:

- Labor-intensive, requiring operators to handle most of the process manually.

- Limited speed and efficiency, making them unsuitable for high-volume production.

- Semi-Automatic Shrink Wrapping Machines

Semi-automatic shrink wrapping machines strike a balance between manual and automated operations. They automate some tasks, such as film sealing and heat application, while still requiring manual intervention for loading bottles onto the conveyor system.

Key Features:

- Increased Efficiency: These machines offer faster operation compared to manual machines, making them ideal for medium-sized businesses.

- Customizable Settings: Operators can adjust settings like film tension and heat levels to accommodate various bottle types.

- Cost-Effectiveness: Less expensive than fully automated machines while offering a significant efficiency boost.

Applications:

- Medium-sized production lines in industries like beverages, cosmetics, and pharmaceuticals.

- Businesses transitioning from manual to automated systems.

Challenges:

- Requires some manual labor, which may limit production speed.

- Suitable for medium volumes but may not keep up with high-demand production lines.

- Automatic Shrink Wrapping Machines

Automatic shrink wrapping machines are fully automated systems designed for high-speed production lines. These machines require minimal human intervention, handling everything from bottle loading to film application, sealing, and heat shrinking.

Key Features:

- High-Speed Operation: Capable of wrapping thousands of bottles per hour, ensuring high productivity.

- Precision: Automated systems ensure consistent and accurate wrapping for every bottle.

- Versatility: Can handle various bottle sizes, shapes, and bundle configurations.

Applications:

- Large-scale manufacturing facilities.

- Industries with high-volume production demands, such as bottled water, soft drinks, and pharmaceuticals.

Challenges:

- Higher initial investment compared to manual and semi-automatic systems.

- Requires trained operators for setup and occasional troubleshooting.

- Shrink Tunnel Machines

Shrink tunnel machines are a specialized form of shrink wrapping equipment that use a conveyor system to move wrapped bottles through a shrink wrap tunnel, where heat is applied. The heat causes the film to shrink tightly around the bottles.

Key Features:

- Consistent Heating: Advanced heating elements ensure even heat distribution for precise shrinkage.

- High-Volume Capability: Designed for continuous operation, making them ideal for large-scale production lines.

- Integration: Can be seamlessly integrated with other automated systems, such as filling and labeling machines.

Applications:

- High-speed beverage production lines.

- Large-scale pharmaceutical and cosmetic packaging.

- Bundling multiple bottles for retail distribution.

Challenges:

- Higher energy consumption due to continuous heating.

- Requires adequate space for installation and operation.

How Bottle Shrink Wrapping Machines Work

The bottle shrink wrapping process involves a series of precise steps, each contributing to the secure and professional packaging of bottles. Here’s a detailed breakdown of the process:

- Bottle Loading

Manual or Automated Loading:

The process begins with loading the bottles onto a conveyor system. This step can vary depending on the type of machine:

- Manual Machines: Operators manually place the bottles on the conveyor or wrapping area.

- Semi-Automatic Machines: Bottles are loaded manually but are moved through the system automatically.

- Automatic Machines: A fully automated feeding system loads the bottles onto the conveyor without manual intervention.

Importance:

Accurate loading ensures that bottles are positioned correctly for the subsequent steps, minimizing errors in wrapping or sealing.

- Film Application

Wrapping the Bottles:

The next step involves applying the shrink wrap film around the bottles. The method of application depends on the machine type:

- Individual Wrapping: For single bottles, the film is wrapped around each bottle separately.

- Bundling: For multi-pack applications, the film wraps around a group of bottles, such as six-packs or twelve-packs.

Film Types:

Machines typically use heat-shrinkable films designed to shrink uniformly when heated. The film is unwound from a roll and precisely positioned to cover the bottles.

Customization:

Operators can adjust settings like film tension and size to accommodate different packaging requirements, ensuring a snug fit for all bottle types.

- Sealing

Creating a Secure Package:

Once the film is applied, the machine seals the edges to form a complete enclosure around the bottles. This is achieved using heat or pressure-sensitive sealing mechanisms.

Seal Types:

- Side Seals: Located along the sides of the package, ensuring a neat appearance.

- End Seals: Found at the ends of the film for additional security.

Importance:

Proper sealing is crucial for maintaining the integrity of the package. A strong seal ensures the film stays in place during heat shrinking and provides a tamper-evident barrier.

- Heat Shrinking

Applying Heat:

The wrapped bottles are then passed through a shrink wrap tunnel or exposed to a heat source. The heat causes the shrink wrap film to contract and conform tightly to the shape of the bottles or bundle.

Shrink Tunnel Machines:

These machines are equipped with advanced heating elements and conveyor systems that move the bottles at a consistent speed, ensuring uniform heat distribution.

Precision Control:

Operators can adjust the temperature and conveyor speed to suit different film types and bottle sizes, preventing overheating or under-shrinking.

- Cooling

Setting the Wrap:

After heat shrinking, the bottles are cooled to set the wrap in place. This step is essential for ensuring the film maintains its tight fit and provides a durable, long-lasting seal.

Cooling Methods:

- Air Cooling: Fans or blowers cool the bottles as they exit the shrink tunnel.

- Ambient Cooling: Bottles are allowed to cool naturally at room temperature.

Benefits:

- Cooling prevents the film from loosening after shrinking.

- It ensures the package is ready for immediate handling or further processing, such as labeling or boxing.

The packaging process facilitated by bottle shrink wrapping machines is a seamless integration of technology and efficiency. From loading bottles to applying shrink wrap film, sealing, heat shrinking, and cooling, each step is designed to deliver a professional, secure, and visually appealing package. By understanding the types of machines and how they work, businesses can make informed decisions that enhance their production lines and meet the demands of modern packaging requirements.

Automation: The Key to Efficiency

In the rapidly evolving packaging industry, automation has revolutionized how businesses handle high-volume production demands. By integrating automatic shrink wrapping machines into production lines, companies can achieve unparalleled efficiency, consistency, and cost savings. Here’s how automation is a game-changer:

- Consistency

One of the standout benefits of automation is the ability to ensure every product is packaged to the same standard. Automatic shrink wrapping machines eliminate the variability that comes with manual wrapping, producing uniform results every time.

- Precise Film Application: Automated systems consistently apply shrink wrap film with the correct tension and alignment, ensuring a professional appearance for every package.

- Reduced Errors: By minimizing human intervention, automation reduces the likelihood of errors such as misaligned wraps or loose seals.

- Improved Quality Control: Automated machines can integrate inspection systems to identify and rectify issues before the products leave the production line.

- Increased Output

For businesses with high production demands, automatic shrink wrapping machines provide unmatched speed and productivity. These machines are designed to process large volumes of products with minimal downtime.

- Thousands of Bottles Per Hour: Depending on the model, these machines can wrap hundreds or even thousands of bottles in a single hour, meeting the demands of large-scale production facilities.

- Continuous Operation: Automation allows for uninterrupted operation, reducing delays caused by manual labor or equipment adjustments.

- Scalable for Growth: Businesses can rely on automated systems to keep up with increasing production targets as they expand.

- Labor Savings

Automating repetitive tasks, such as wrapping and sealing, significantly reduces the need for manual labor. This not only lowers operational costs but also allows businesses to allocate resources to more critical areas.

- Fewer Operators Needed: An automated system can perform the work of several employees, minimizing labor requirements on the packaging line.

- Reduced Fatigue: By handling labor-intensive tasks, machines reduce physical strain on workers, improving overall workplace safety and productivity.

- Focus on Value-Added Tasks: With labor freed from repetitive tasks, employees can focus on quality control, machine optimization, and other high-value activities.

- Scalability

As businesses grow, their production demands often increase. Automatic shrink wrapping machines are designed to scale with these needs, offering flexibility to handle higher volumes or adapt to new products.

- Easily Upgradable: Many systems allow for upgrades, such as increased speed or compatibility with additional bottle sizes.

- Adaptability: Modern machines can handle a wide range of bottle types, shapes, and materials, making them suitable for evolving product lines.

- Future-Proofing: Investing in automation ensures that your packaging line can adapt to industry changes and growing consumer demands.

How to Choose the Right Bottle Shrink Wrapping Machine

Selecting the right bottle shrink wrapping machine is critical for optimizing your production line. Consider the following factors to make an informed decision:

- Production Capacity

Evaluate your current production needs and plan for future growth. Machines with higher throughput capabilities may require a larger upfront investment but will save costs as your business scales.

- High-Speed Models: For businesses with high-volume demands, look for machines capable of wrapping thousands of bottles per hour.

- Customizable Speed: Choose a machine that allows for speed adjustments to accommodate fluctuations in production.

- Bottle Type

Not all machines are compatible with every bottle shape, size, or material. Ensure the machine you choose is versatile enough to handle your specific packaging needs.

- Variety of Shapes and Sizes: Look for machines that can accommodate standard and non-standard bottle designs.

- Specialty Bottles: If you package fragile or uniquely shaped bottles, confirm the machine has the features to handle them without damage.

- Energy Efficiency

Energy consumption is a significant operational cost. Opt for machines designed with energy-efficient components to minimize expenses while maintaining performance.

- Low Power Consumption: Modern machines often feature energy-saving modes that reduce power usage during downtime.

- Efficient Heating Systems: Look for machines with advanced heating elements that provide precise heat application without wasting energy.

- Ease of Maintenance

Downtime for maintenance can disrupt production schedules. Choose a machine with user-friendly maintenance features that simplify cleaning, repairs, and part replacements.

- Self-Diagnostic Tools: Machines with built-in diagnostics can identify issues early, reducing troubleshooting time.

- Accessible Components: Ensure key parts are easy to access and replace without extensive disassembly.

- Budget

While initial costs are important, prioritize machines that offer long-term value in terms of durability, efficiency, and reliability.

- Cost-Benefit Analysis: Balance upfront costs with operational savings and scalability.

- Durability: Invest in high-quality machines with a proven track record for longevity and performance.

Maintenance Tips for Bottle Shrink Wrapping Machines

Proper maintenance ensures your machine operates efficiently and lasts for years. Implement these best practices to keep your shrink wrapping machine in top condition:

- Regular Cleaning

Dust, debris, and film residue can accumulate on the machine’s components, affecting performance. Schedule regular cleaning to maintain smooth operation.

- Conveyor Belts: Clean belts to prevent slippage or bottle misalignment.

- Heat Tunnels: Remove any buildup from the heating elements to ensure consistent heat distribution.

- Rollers and Guides: Wipe down rollers and guides to prevent jams and ensure smooth film movement.

- Inspect Heating Elements

The heating elements in shrink tunnel machines are critical for achieving a tight, uniform shrink. Regularly inspect these components to ensure they are functioning correctly.

- Check for Wear and Tear: Replace worn or damaged elements to maintain consistent performance.

- Monitor Temperature Settings: Ensure the temperature is calibrated correctly to prevent overheating or under-shrinking.

- Lubrication

Moving parts like rollers, gears, and conveyor systems require lubrication to prevent friction and wear.

- Use Manufacturer-Recommended Lubricants: Avoid using improper lubricants that can damage components.

- Create a Lubrication Schedule: Regular lubrication prevents unnecessary downtime and extends the life of the machine.

- Calibrate Sensors

Sensors play a vital role in detecting bottles and ensuring accurate film application. Keep these components properly calibrated for optimal performance.

- Periodic Calibration: Schedule regular checks to maintain sensor accuracy.

- Clean Sensors: Remove dust or debris that could interfere with sensor functionality.

- Replace Worn Parts

Proactively replace worn components before they fail, reducing the risk of unexpected breakdowns.

- Common Parts to Replace: Monitor belts, seals, and rollers for signs of wear.

- Keep Spare Parts On Hand: Stock critical components to minimize downtime during repairs.

Industries That Benefit from Bottle Shrink Wrapping Machines

The versatility and efficiency of bottle shrink wrapping machines make them indispensable across multiple industries:

- Beverage Industry

The beverage industry relies heavily on shrink wrapping for packaging bottled water, soft drinks, juices, and alcoholic beverages.

- Protection Against Moisture: Shrink wrapping provides a barrier against water and other external contaminants.

- Bundling Capabilities: Machines can bundle bottles into multi-packs, improving convenience for consumers and retailers.

- Pharmaceutical Industry

Pharmaceutical companies use bottle shrink wrap machines to meet stringent safety and hygiene standards.

- Tamper-Evident Packaging: Shrink wrap provides a secure seal that ensures the integrity of medicinal products.

- Regulatory Compliance: Automated systems help meet industry-specific packaging regulations.

- Cosmetic Industry

Fragile and high-value cosmetic products, such as perfume and skincare bottles, benefit from shrink wrapping.

- Enhanced Protection: The wrap minimizes the risk of breakage during transportation.

- Transparent Wrapping: Allows consumers to view the product while protecting it from dust and scratches.

- Food Industry

The food industry uses shrink wrapping for sauces, syrups, and other bottled consumables.

- Maintains Hygiene: Shrink wrap prevents contamination and ensures the product remains fresh.

- Improved Shelf Appeal: Clear wrapping enhances visibility and branding.

Automation and proper maintenance are key to achieving operational efficiency and long-term success with bottle shrink wrapping machines. These machines offer versatility, scalability, and cost savings, making them indispensable for a wide range of industries. By choosing the right machine, following regular maintenance practices, and leveraging automation, businesses can ensure consistent, high-quality packaging that meets both consumer expectations and industry standards.

The Future of Bottle Shrink Wrapping Machines

As technology advances, bottle shrink wrapping machines are becoming smarter and more efficient. Features like IoT connectivity, AI-driven diagnostics, and enhanced energy efficiency are shaping the future of packaging. These innovations promise faster operations, reduced energy consumption, and seamless integration into automated production lines.

Conclusion

Bottle shrink wrapping machines are a cornerstone of modern packaging lines, offering unmatched benefits in terms of efficiency, cost-effectiveness, and product protection. Whether you’re packaging beverages, pharmaceuticals, or cosmetics, these machines ensure your products are well-protected and visually appealing, enhancing both consumer trust and brand value.

By investing in the right bottle shrink wrapping machine, businesses can streamline operations, reduce costs, and meet the ever-growing demands of their industry. As technology continues to evolve, these machines will remain indispensable tools for achieving operational excellence and staying competitive in a dynamic market.