Heat Shrink Machine: An In-depth Guide by Dunamis Machines

In today’s fast-paced industrial world, packaging plays a critical role in ensuring product safety, enhancing visual appeal, and facilitating transportation. One technology that has revolutionized packaging is the heat shrink machine. Dunamis Machines, a leader in industrial packaging

solutions, brings you an exhaustive guide on heat shrink machines, their types, applications, and benefits. This guide will help you understand why investing in a heat shrink machine can be a game-changer for your business.

What is a Heat Shrink Machine?

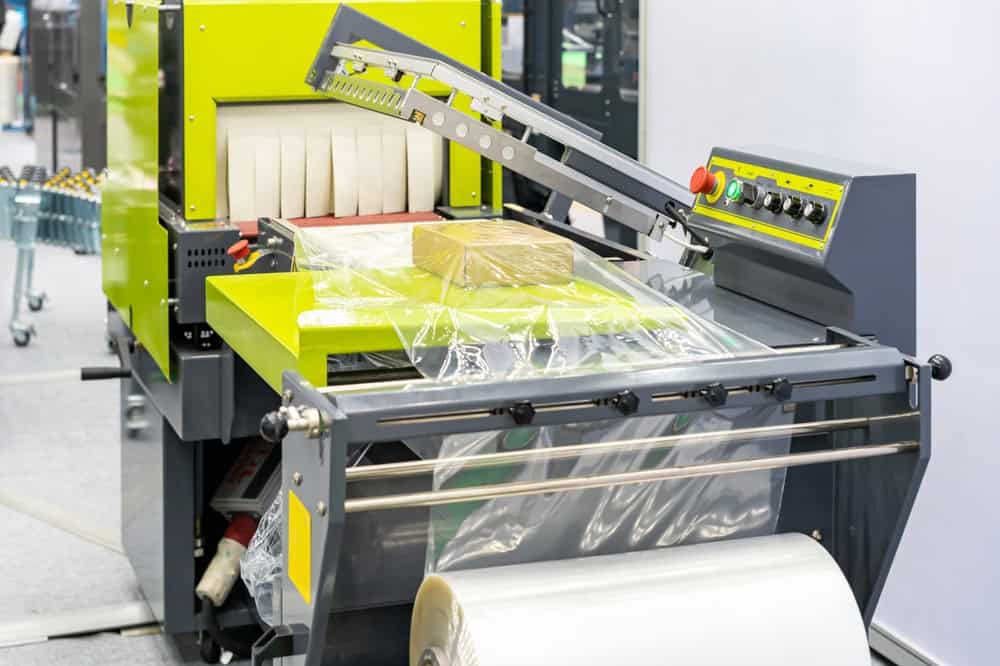

A heat shrink machine is a device used to apply heat to shrinkable plastic film tightly around products, providing a secure and tamper-proof seal. This process is widely used in various industries, including food and beverage, pharmaceuticals, electronics, and manufacturing, due to its efficiency and effectiveness.

How Does a Heat Shrink Machine Work?

The operation of a heat shrink machine involves several key steps:

- Wrapping: The product is wrapped with a heat shrink film, usually made of materials like polyolefin, PVC, or polyethylene.

- Sealing: The film is sealed using a heat sealer to create a closed envelope around the product.

- Shrinking: The sealed product passes through a heat tunnel where hot air or infrared heat is applied, causing the film to shrink tightly around the product.

Types of Heat Shrink Machines

Heat shrink machines come in various configurations to cater to different packaging needs. Here are the main types:

- L-Bar Sealers: These machines use an L-shaped sealing bar to cut and seal the shrink film around the product. They are ideal for medium to high-volume packaging and provide a clean and professional finish.

- I-Bar Sealers: Also known as straight bar sealers, these machines use a single straight bar to seal the film. They are suitable for low to medium-volume packaging and are often used in conjunction with a heat gun.

- Heat Tunnels: These machines consist of a conveyor belt that transports the wrapped product through a heated chamber. Heat tunnels are perfect for high-volume packaging and provide uniform heat distribution for consistent shrinkage.

- Chamber Machines: These combine sealing and shrinking in a single chamber, making them compact and efficient. They are ideal for small to medium-sized businesses looking to streamline their packaging process.

Benefits of Using a Heat Shrink Machine

Investing in a heat shrink machine offers numerous benefits:

- Enhanced Protection: Heat shrink film provides a tight and secure seal, protecting products from dust, moisture, and tampering.

- Improved Aesthetics: The clear, glossy finish of shrink film enhances the visual appeal of products, making them more attractive to consumers.

- Cost Efficiency: Heat shrink machines reduce the need for bulky packaging materials, lowering shipping costs and storage space requirements.

- Versatility: These machines can package a wide range of products, from small items like electronics to large items like pallets.

- Increased Productivity: Automated heat shrink machines streamline the packaging process, allowing businesses to package products faster and more efficiently.

Applications of Heat Shrink Machines

Heat shrink machines are used across various industries for multiple applications. Here are some common uses:

- Food and Beverage Industry: Heat shrink machines are used to package food items like cheese, meats, and baked goods, as well as beverages like bottled water and soft drinks.

- Pharmaceutical Industry: These machines ensure that medicines and medical devices are securely sealed, maintaining their integrity and preventing contamination.

- Electronics Industry: Heat shrink machines provide a protective barrier for electronic devices, safeguarding them against static, dust, and moisture.

- Retail Industry: From cosmetics to toys, heat shrink machines are used to package a wide range of retail products, enhancing their shelf appeal and protection.

- Manufacturing Industry: Large items like machinery parts and tools are often wrapped with shrink film to protect them during transportation and storage.

Choosing the Right Heat Shrink Machine

Selecting the right heat shrink machine for your business depends on several factors:

- Volume of Production: High-volume operations may require a continuous motion heat shrink machine with a conveyor belt and heat tunnel, while low-volume operations might benefit from a manual or semi-automatic L-bar sealer.

- Product Size and Shape: Consider the dimensions and shape of the products you need to package. Chamber machines are versatile and can handle various sizes, whereas heat tunnels are better suited for larger items.

- Film Type: Different machines are compatible with different types of shrink film. Ensure the machine you choose works with the film material you plan to use.

- Budget: Determine your budget and consider the long-term benefits of investing in a more expensive, high-quality machine that can increase productivity and reduce operational costs.

- Ease of Use: Look for machines with user-friendly controls and features that simplify the packaging process, such as adjustable heat settings and automatic film feeding.

Maintenance and Safety Tips for Heat Shrink Machines

Proper maintenance and adherence to safety guidelines are crucial for the efficient operation of heat shrink machines. Here are some tips:

- Regular Cleaning: Keep the machine clean and free from dust and debris to ensure smooth operation. Clean the sealing bar and heat tunnel regularly to prevent film buildup.

- Routine Inspections: Conduct regular inspections to identify and address any wear and tear on machine components, such as belts, motors, and heating elements.

- Safety Training: Ensure all operators are trained on the safe use of the machine, including how to handle the heat source and what protective gear to wear.

- Proper Ventilation: Heat shrink machines generate heat and fumes, so ensure proper ventilation in the packaging area to maintain a safe working environment.

- Emergency Procedures: Establish clear emergency procedures for dealing with malfunctions or accidents, including how to quickly shut down the machine.

Innovations in Heat Shrink Technology

The packaging industry continues to evolve, and heat shrink technology is no exception. Here are some recent innovations:

- Eco-Friendly Films: Manufacturers are developing biodegradable and recyclable shrink films to reduce environmental impact.

- Energy-Efficient Machines: Newer models of heat shrink machines are designed to consume less energy, making them more sustainable and cost-effective.

- Smart Controls: Advanced heat shrink machines feature smart controls and automation, allowing for precise temperature and speed adjustments, as well as remote monitoring and diagnostics.

- Customizable Solutions: Manufacturers are offering customizable heat shrink machines that can be tailored to specific packaging needs, ensuring optimal performance and efficiency.

Dunamis Machines: Your Partner in Packaging Solutions

At Dunamis Machines, we are committed to providing our customers with the best packaging solutions. Our range of heat shrink machines is designed to meet the diverse needs of businesses across various industries. With a focus on quality, innovation, and customer satisfaction, we offer:

- Comprehensive Product Line: From entry-level chamber machines to high-volume heat tunnels, we have a heat shrink machine for every application.

- Expert Support: Our team of experts is available to help you choose the right machine, provide installation and training, and offer ongoing support and maintenance.

- Custom Solutions: We understand that every business has unique packaging needs. That’s why we offer customizable solutions to ensure our machines meet your specific requirements.

- High-Quality Materials: We use only the highest quality materials and components in our machines to ensure durability, reliability, and superior performance.

- Competitive Pricing: We offer competitive pricing on all our heat shrink machines, providing you with the best value for your investment.

Investing in a heat shrink machine from Dunamis Machines can significantly enhance your packaging process, offering benefits such as improved product protection, enhanced aesthetics, and increased productivity. By understanding the different types of machines, their applications, and the factors to consider when choosing the right machine, you can make an informed decision that aligns with your business needs.

Dunamis Machines is dedicated to helping businesses achieve their packaging goals with our state-of-the-art heat shrink machines and expert support. Whether you’re looking to streamline your packaging process, reduce costs, or enhance the appeal of your products, we have the solution for you.

Explore our range of heat shrink machines today and discover how Dunamis Machines can help you take your packaging to the next level.

The Role of Heat Shrink Machines in the Manufacturing Industry

Heat shrink machines have become indispensable in the manufacturing industry due to their versatility, efficiency, and reliability. These machines are used to apply heat shrink materials—typically plastic films—that contract tightly over products or components when heat is applied. This process offers numerous benefits, including protection, insulation, and branding. In this comprehensive overview, we will explore how heat shrink machines are utilized across various manufacturing sectors, their benefits, and the innovations driving their use.

Applications of Heat Shrink Machines in Manufacturing

- Packaging and Protection

One of the primary uses of heat shrink machines is in packaging. Manufacturers use these machines to create tamper-evident seals, protect products from dust, moisture, and contaminants, and improve product presentation. Heat shrink packaging is commonly used for:

– Food and Beverages: Heat shrink films are used to wrap bottles, cans, and food packages. This type of packaging keeps the products fresh and secure, extending their shelf life.

– Consumer Electronics: Devices such as smartphones, tablets, and accessories are often packaged using heat shrink films. This not only protects the products during transportation but also provides a professional appearance that enhances customer appeal.

– Pharmaceuticals: Heat shrink wrapping ensures that medical products and drugs are safe from tampering and contamination, complying with stringent industry regulations.

- Electrical and Electronic Insulation

Heat shrink machines are extensively used for insulating electrical wires, cables, and components. The heat shrink tubing used in this process provides a protective layer that ensures electrical safety and durability. Applications include:

– Cable Harnesses: In automotive and aerospace manufacturing, heat shrink tubing is used to bundle and protect wire harnesses. This prevents abrasion, reduces electrical interference, and enhances the overall reliability of the electrical system.

– Connector Insulation: Heat shrink tubes are used to insulate connectors and terminals, preventing short circuits and improving the durability of electrical connections.

– Circuit Board Protection: In electronics manufacturing, heat shrink films are used to protect printed circuit boards (PCBs) from environmental factors, ensuring their longevity and performance.

- Branding and Labeling

Heat shrink machines also play a crucial role in branding and labeling. Heat shrink sleeves can be printed with high-quality graphics, logos, and product information, making them an excellent choice for product branding. This is particularly prevalent in:

– Beverage Industry: Bottles and cans are often wrapped with shrink sleeves that display vibrant, full-color graphics. This enhances brand visibility and provides a 360-degree branding surface.

– Cosmetics: Heat shrink labels are used on cosmetic containers to provide an attractive, tamper-evident seal that also conveys brand identity and product details.

– Household Goods: Products such as detergents, cleaning supplies, and other household items utilize heat shrink labeling for both branding and functional purposes.

Benefits of Heat Shrink Machines

- Versatility

Heat shrink machines are versatile and can be used across a wide range of industries and applications. They can handle various shapes and sizes of products, from small electronic components to large industrial parts. This adaptability makes them a valuable asset in any manufacturing setting.

- Enhanced Protection

Heat shrink films provide excellent protection against environmental factors such as moisture, dust, and physical damage. This is particularly important for products that need to maintain their integrity during storage and transportation. By using heat shrink machines, manufacturers can ensure that their products arrive in perfect condition.

- Cost Efficiency

Using heat shrink machines can lead to significant cost savings. The process is relatively quick and requires minimal labor, reducing production costs. Additionally, the protective qualities of heat shrink films can reduce the need for additional packaging materials and lower the risk of product damage, further saving costs.

- Improved Aesthetics

Heat shrink packaging offers a sleek and professional appearance, which can enhance product appeal and brand perception. The tight-fitting film conforms to the shape of the product, providing a clean and attractive look. This is especially beneficial in consumer markets where visual appeal is crucial.

- Tamper Evident

Heat shrink packaging acts as a tamper-evident seal, providing consumers with confidence that the product has not been altered or contaminated. This is particularly important in the food, beverage, and pharmaceutical industries where product safety is paramount.

- Environmental Benefits

Advancements in heat shrink film technology have led to the development of eco-friendly materials. Many heat shrink films are now made from recyclable or biodegradable materials, reducing the environmental impact of packaging. Manufacturers can also minimize waste by using precise amounts of shrink film, aligning with sustainable practices.

Innovations in Heat Shrink Machines

- Automated Systems

Modern heat shrink machines are increasingly automated, enhancing efficiency and reducing the need for manual intervention. Automated systems can handle high volumes of products with consistent quality, making them ideal for large-scale manufacturing operations.

- Advanced Control Systems

Newer models of heat shrink machines come equipped with advanced control systems that allow for precise temperature and speed adjustments. This ensures optimal shrinkage and reduces the risk of overheating or damaging the product. Manufacturers can achieve consistent results with minimal waste.

- Integration with Production Lines

Heat shrink machines can be seamlessly integrated into existing production lines, streamlining the packaging process. This integration allows for continuous operation and reduces downtime, significantly improving overall production efficiency.

- Customization Capabilities

Manufacturers can now customize heat shrink machines to meet specific requirements. Whether it’s adjusting the size of the shrink tunnel or incorporating additional features such as printing or labeling, these machines can be tailored to fit unique production needs.

- Energy Efficiency

Energy-efficient heat shrink machines are becoming more prevalent, reducing operational costs and environmental impact. These machines utilize advanced heating elements and insulation materials to minimize energy consumption while maintaining high performance.

Heat shrink machines are a vital component of the manufacturing industry, offering a wide range of applications and benefits. From packaging and protection to insulation and branding, these machines enhance efficiency, reduce costs, and improve product quality. As technology continues to advance, the capabilities of heat shrink machines will only expand, driving further innovations and improvements in manufacturing processes.

For manufacturers looking to stay competitive and meet the demands of modern production, investing in high-quality heat shrink machines from trusted suppliers like Dunamis Machines is a wise decision. With their commitment to quality, innovation, and customer satisfaction, Dunamis Machines provides the solutions needed to optimize manufacturing operations and achieve long-term success.

The Role of Heat Shrink Machines in the Manufacturing Industry

Heat shrink machines have become indispensable in the manufacturing industry due to their versatility, efficiency, and reliability. These machines are used to apply heat shrink materials—typically plastic films—that contract tightly over products or components when heat is applied. This process offers numerous benefits, including protection, insulation, and branding. In this comprehensive overview, we will explore how heat shrink machines are utilized across various manufacturing sectors, their benefits, the innovations driving their use, and the specific process of how heat is applied.

Applications of Heat Shrink Machines in Manufacturing

- Packaging and Protection

One of the primary uses of heat shrink machines is in packaging. Manufacturers use these machines to create tamper-evident seals, protect products from dust, moisture, and contaminants, and improve product presentation. Heat shrink packaging is commonly used for:

– Food and Beverages: Heat shrink films are used to wrap bottles, cans, and food packages. This type of packaging keeps the products fresh and secure, extending their shelf life.

– Consumer Electronics: Devices such as smartphones, tablets, and accessories are often packaged using heat shrink films. This not only protects the products during transportation but also provides a professional appearance that enhances customer appeal.

– Pharmaceuticals: Heat shrink wrapping ensures that medical products and drugs are safe from tampering and contamination, complying with stringent industry regulations.

- Electrical and Electronic Insulation

Heat shrink machines are extensively used for insulating electrical wires, cables, and components. The heat shrink tubing used in this process provides a protective layer that ensures electrical safety and durability. Applications include:

– Cable Harnesses: In automotive and aerospace manufacturing, heat shrink tubing is used to bundle and protect wire harnesses. This prevents abrasion, reduces electrical interference, and enhances the overall reliability of the electrical system.

– Connector Insulation: Heat shrink tubes are used to insulate connectors and terminals, preventing short circuits and improving the durability of electrical connections.

– Circuit Board Protection: In electronics manufacturing, heat shrink films are used to protect printed circuit boards (PCBs) from environmental factors, ensuring their longevity and performance.

- Branding and Labeling

Heat shrink machines also play a crucial role in branding and labeling. Heat shrink sleeves can be printed with high-quality graphics, logos, and product information, making them an excellent choice for product branding. This is particularly prevalent in:

– Beverage Industry: Bottles and cans are often wrapped with shrink sleeves that display vibrant, full-color graphics. This enhances brand visibility and provides a 360-degree branding surface.

– Cosmetics: Heat shrink labels are used on cosmetic containers to provide an attractive, tamper-evident seal that also conveys brand identity and product details.

– Household Goods: Products such as detergents, cleaning supplies, and other household items utilize heat shrink labeling for both branding and functional purposes.

Benefits of Heat Shrink Machines

- Versatility

Heat shrink machines are versatile and can be used across a wide range of industries and applications. They can handle various shapes and sizes of products, from small electronic components to large industrial parts. This adaptability makes them a valuable asset in any manufacturing setting.

- Enhanced Protection

Heat shrink films provide excellent protection against environmental factors such as moisture, dust, and physical damage. This is particularly important for products that need to maintain their integrity during storage and transportation. By using heat shrink machines, manufacturers can ensure that their products arrive in perfect condition.

- Cost Efficiency

Using heat shrink machines can lead to significant cost savings. The process is relatively quick and requires minimal labor, reducing production costs. Additionally, the protective qualities of heat shrink films can reduce the need for additional packaging materials and lower the risk of product damage, further saving costs.

- Improved Aesthetics

Heat shrink packaging offers a sleek and professional appearance, which can enhance product appeal and brand perception. The tight-fitting film conforms to the shape of the product, providing a clean and attractive look. This is especially beneficial in consumer markets where visual appeal is crucial.

- Tamper Evident

Heat shrink packaging acts as a tamper-evident seal, providing consumers with confidence that the product has not been altered or contaminated. This is particularly important in the food, beverage, and pharmaceutical industries where product safety is paramount.

- Environmental Benefits

Advancements in heat shrink film technology have led to the development of eco-friendly materials. Many heat shrink films are now made from recyclable or biodegradable materials, reducing the environmental impact of packaging. Manufacturers can also minimize waste by using precise amounts of shrink film, aligning with sustainable practices.

The Heat Shrink Process: How Heat is Applied

The process of applying heat shrink materials involves several key steps, each crucial for achieving a tight and protective seal around the product:

- Preparation

Before the heat shrink process begins, the product is prepared and placed in the desired position. The heat shrink film or tubing is then cut to the appropriate size, ensuring it will cover the product completely once shrunk.

- Application of Film or Tubing

The heat shrink film or tubing is placed over the product. For film applications, this might involve wrapping the product and sealing the edges. For tubing, the product is inserted into the pre-cut tube.

- Heat Application

This is the critical step where the magic happens. Heat is applied to the shrink material using one of several methods:

– Heat Guns: Handheld heat guns are often used for smaller, more precise applications. The operator directs the heat gun over the shrink material, causing it to contract and conform to the shape of the product.

– Shrink Tunnels: For high-volume or continuous production lines, shrink tunnels are used. These tunnels are equipped with heaters that provide consistent and even heat as products pass through on a conveyor belt. This method ensures uniform shrinkage and is highly efficient for large-scale operations.

– Ovens: In some cases, products are placed in heat shrink ovens where the entire product is uniformly heated. This method is typically used for products that require a longer exposure to heat or for bulk shrink applications.

- Cooling and Setting

After the heat has been applied and the material has shrunk tightly around the product, it is allowed to cool. Cooling solidifies the material, ensuring it retains its new shape and provides a secure, protective layer.

- Quality Control

Finally, the labeled and protected product undergoes a quality control check to ensure that the shrinkage is uniform and that the film or tubing has adhered properly. Any imperfections are identified and rectified to maintain high standards.

Innovations in Heat Shrink Machines

- Automated Systems

Modern heat shrink machines are increasingly automated, enhancing efficiency and reducing the need for manual intervention. Automated systems can handle high volumes of products with consistent quality, making them ideal for large-scale manufacturing operations.

- Advanced Control Systems

Newer models of heat shrink machines come equipped with advanced control systems that allow for precise temperature and speed adjustments. This ensures optimal shrinkage and reduces the risk of overheating or damaging the product. Manufacturers can achieve consistent results with minimal waste.

- Integration with Production Lines

Heat shrink machines can be seamlessly integrated into existing production lines, streamlining the packaging process. This integration allows for continuous operation and reduces downtime, significantly improving overall production efficiency.

- Customization Capabilities

Manufacturers can now customize heat shrink machines to meet specific requirements. Whether it’s adjusting the size of the shrink tunnel or incorporating additional features such as printing or labeling, these machines can be tailored to fit unique production needs.

- Energy Efficiency

Energy-efficient heat shrink machines are becoming more prevalent, reducing operational costs and environmental impact. These machines utilize advanced heating elements and insulation materials to minimize energy consumption while maintaining high performance.

Conclusion

Heat shrink machines are a vital component of the manufacturing industry, offering a wide range of applications and benefits. From packaging and protection to insulation and branding, these machines enhance efficiency, reduce costs, and improve product quality. The precise process of applying heat to shrink materials ensures that products are securely and attractively packaged, meeting the high standards of modern manufacturing.

For manufacturers looking to stay competitive and meet the demands of modern production, investing in high-quality heat shrink machines from trusted suppliers like Dunamis Machines is a wise decision. With their commitment to quality, innovation, and customer satisfaction, Dunamis Machines provides the solutions needed to optimize manufacturing operations and achieve long-term success.