Our Products

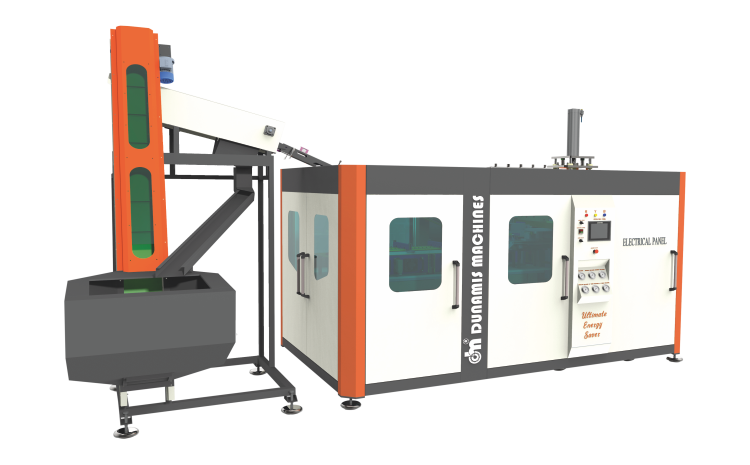

DM-LNFAE3L Online PET Blowing Machine

TECHNICAL SPECIFICATION:

| MACHINE SPECIFICATION | ||

| Machine Category | Fully Automatic | |

| Machine Model | DM-LNFA3L | |

| No of Cavities | 3 Cavity | |

| Production Capacity (Bottles/Hour) | 4000BPH for 300ml | |

| (Depending on Moulds and pre-form Quality) | 3800BPH for 500ml | |

| 3600BPH for 1000ml | ||

| Blowing Capacity | 100ml – 2000ml | |

| Bottle Outlet | Through Air Conveyor | |

| Size of the Mould (Width x Thickness) | 120mm x 385mm | |

| CONTAINER SPECIFICATION | ||

| Types of Bottles Blowing | Water, Juice & Soda | |

| Types of Preform | Alaska & PCO | |

| Max. Neck Diameter | 28mm | |

| Max. Diameter of Bottle | 105mm | |

| Max. Height of the Bottle | 340mm | |

| ELECTRICAL SYSTEM | ||

| Pre-heating System | Near Infrared | |

| No of Heaters | 16 Nos | |

| Heater Capacity | 1500 Watts, 220V AC | |

| Machine Connected Power | 9KW, 3 Phase | |

| Machine with accessories Connected Power | 41.5KW, 3 Phase | |

| Total Power Consumption (Include accessories) | 29KWH (Units) | |

| AIR SYSTEM | ||

| Blowing Pressure | 20Bar | |

| Working Pressure | 6Bar | |

| Air Consumption | 74CFM | |

| REQUIRED ACCESSORIES | ||

| Compressor Capacity (High Pressure) | 30HP/25Bar/82CFM | |

| Air Dryer Capacity | 100CFM/25Bar | |

| Water Chiller Capacity | 4.5Ton@10 C | |

| Cooling Tower | 20 TR | |

MACHINE FEATURES:

Our machine has simple innovative design and ultimate energy saving. It is engineered for efficiency and maximum production speed.

- Advanced Infrared Preheating System for Upto 30% Power Saving.

- Rapid High-Pressure Valves used for Blowing Functions.

- Incremental Heater Settings by 1% to 199% for Accurate Pre-form Heat Setting.

- Air & Water Lines are Push & Pull System for Easy Maintenance.

- Air Recovery System is to recover & reuse the blowing air.

- After Blowing orientated ready bottle online air conveyor for feeding filling machine automatically.

- No Manpower needed for Preform Feeding.

- Long Life PU Seal Cylinders and Higher Accuracy Valves used for Low Pressure Control System.

- IP67 Grade Sensors used for Higher Accuracy & Long Life.

- Advanced PLC Based System with 10” Multi colour HMI Unit used for Easy Man Machine Interfacing and Higher Machine Performance.

- Multiple Products Like Mineral Water Bottles, Carbonated Soft Drinks Bottles, Hot Fill Juice Bottles at Low Investment.

- Machine Can Store 50 Mould Recipe Parameters so it helps to reduce Mould Changing Time.

- High Productivity with Low Power Consumption.

- Easy operation & Easy maintenance.

- Production Display with Man Machine Interfacing Facility. The multi colour touch screen display is used to graphically view all the parameters.

- Compact Structure and low maintenance cost.

OUR VALUABLE PARTNERS:

| Components | Brand Name | Country Origin |

| Electrical System | Schneider Electric | France |

| Pneumatic Systems | Festo | Germany |

| Motors & Gear Boxes | Transtech | Taiwan |

| Sensors | P & F Apex | Germany Japan |

| Bearings | NTN | Japan |

| Linear Bearings | HIWIN | Taiwan |

| Cables | Lapp Cables | Germany | Temperature Controller | Autonix | Korea | Linear Bearings | Hiwin | Taiwan |