Different Types of Plastic Molding and Bottle Making Machines

In most cases, the mold is one of the most costly piece of equipment used in a shot molding process. This results from the complexity of the mold and mildew’s layout, which needs accurate attributes as well as making techniques to put together a practical unit. Shot molding produces liquified plastic as well as polycarbonate products via a pressurized mold cavity shaped as a hollow kind of the designated part style. Custom-made plastic shot molding products can vary from small to large-sized parts, as well as they are typically made use of as vehicle products, such as steering wheels, control panel evaluates, side panels, body frameworks, and also bumpers. So whether you are aiming to find plastic shot molding services in Europe, Asia, the United States, or elsewhere, understanding the process for making shot mold and mildews is vital given the expenditure connected with mold and mildew design as well as fabrication.

In shot molding, the high-pressure pressures made use of to form the molten plastic are worsened by the area of the work surface, usually reaching lots of thousands of psi. As a result, the mold and mildew needs to be able to endure these pressures without opening, while likewise standing up to the clamping force needed to hold the material in place. Injection molds are capable of producing very precise and uniform components. Achieving these close tolerances depends on the right combination of design and mold construction and careful selection of the manufacturing process used to create the mold.

So whether you are looking to locate plastic injection molding services in Europe, Asia, the United States, or elsewhere, understanding the process for manufacturing injection molds is vital given the expense associated with mold design and fabrication.

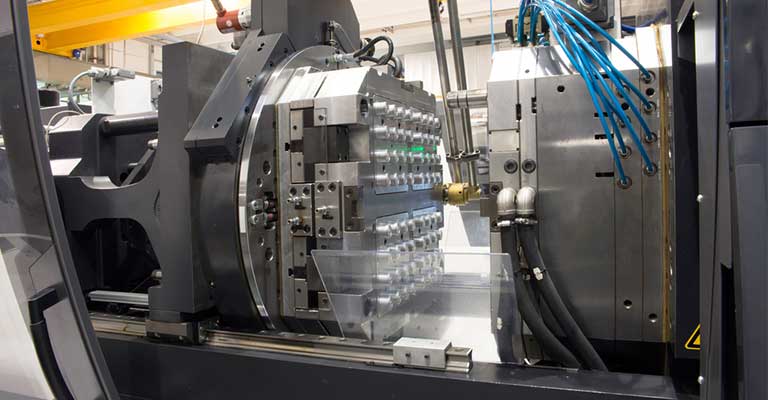

Injection Mold Cavities

The mold cavity is the hollow chamber into which molten plastic is inserted. Most molds can be categorized as single-cavity or multi-cavity designs. Single-cavity molds have relatively lower tooling costs and provide a high degree of precision, but generally have higher expenses per unit and reduced volume capacity. Multi-cavity molds can sometimes have several different parts molded in a single cycle, and they provide comparatively low unit and mold costs. As a result, multi-cavity molds often provide higher volume rates, but they can also suffer from difficulty in matching processing conditions to individual components and maintaining supply levels in multi-stage manufacturing processes.

Injection Mold Materials

Choosing a material for constructing an injection mold depends on a number of factors, including cost-efficiency and product specifications. The size of the product run can also be an important influence, as most materials have differing levels of wear resistance, making them more or less suited for long-term, high-volume production. Likewise, the complexity of the product design and the consequent degree of injection pressure can be important criteria. Composite or reinforced materials are fairly standard, and the beneficial attributes of one material are often combined with those of another. Some of the materials commonly used for mold construction include:

Aluminum: Aluminum is a relatively inexpensive forming material well-suited for injection molds performing low-volume production runs or prototype manufacturing. Aluminum molds are effective for crafting simple shapes, and aluminum’s low strength level and malleability make it easier for mold construction. However, this low strength also reduces the lifespan and wear resistance of aluminum molds, making them ill-suited for long-term projects.

Pre-hardened Steel: This type of steel balances strength with formability. Pre-hardened steel is durable enough to withstand the wear of higher volume product runs, while also being malleable enough to undergo shaping from milling and other standard machining or tooling processes. Pre-hardened steel molds can support relatively complex designs and peripheral features that would fail in aluminum-based counterparts, and they are usually capable of manufacturing cycles that produce hundreds of thousands of parts.

Hardened Steel: Hardened steel molds are designed for high-volume, long-term production runs. They are generally the strongest and most expensive injection molds. The higher cost for this material stems from the heat treatment that occurs midway through its fabrication. After hardening, less conventional shaping methods, such as EDM cutting, must be used to form the mold. Hardened steel is highly resistant to abrasion from plastic resin and wear from pressurized molding, and molds constructed of this material are capable of product runs numbering over a million parts.

Constructing Injection Molds

Injection mold manufacturing is a multi-stage process that emphasizes accuracy and close adherence to design specifications in order to reduce the risk of product failure or damage. A typical procedure would begin with milling or turning the mold forming material, followed by heat-treating (in the case of hardened steel), grinding and fine shaping, and finishing treatments, such as polishing. After the components are prepared, the mold is carefully assembled to ensure it will deliver its intended effect on workpieces. Several considerations, such as tightness to prevent molten plastic from escaping the mold and ventilation to allow air to exit the mold cavity during operations, come to play in the assembly stage. The mold is then tested with a few prototype products to determine its level of precision and quality of construction.

While automation has gained in prevalence in the plastic molding industry, there are still numerous manual processes in use today. For example, bag molding is a method of fabricating thermoset plastic materials into a variety of durable reinforced components, a process that relies mostly on manual control. It involves placing a specialized bag over a plastic workpiece while it is inside a mold cavity, and applying vacuum or compressed air pressure around the bag. Rollers squeeze out air pockets as pressure is directed against the bag, and often heat is introduced to aid in the process. The bag itself is usually an impermeable and flexible cover made of parting film or an elastomeric material.

Bag molding products tend to be compact and strong, with thickness tolerances resembling those offered by injection molding. Bag molding is traditionally employed for manufacturing high performance structural components, such as construction materials, equipment housings, automotive bodies, ship hulls, and a range of military products. It is also often used in conjunction with other molding techniques. This combination of machinery and hand-operated devices allows for quality and attention to detail in fabricating plastic materials.

Mold Preparation

In a standard bag molding process, the elastic bag covers the plastic material within the mold cavity. However, before this can occur, the mold itself must be cleaned, pre-treated, and sealed along the edges. The mold is usually coated with a releasing agent and a gel lubricant, although molds featuring a single curve can sometimes be treated with a plastic film instead. A reinforcing layer of glass fiber can be inserted to provide smoother surface quality, although the key reinforcement is usually a preform composed of a glass thread mat. This preform is shaped to size before being placed into the mold along with any other necessary reinforcing agents or additives.

Bagging and Molding

After the mold has been prepared for bagging and the glass fiber reinforcements have been positioned, the actual fabrication process is ready to begin. In a standard bag molding procedure, the following equipment is usually required to perform the manual stages of the operation:

– Metal rollers in both paddle and disc configurations for flattening trapped air

– Laminating rollers with long hair or short hair bristles for applying bonding resins and gel coatings

– Brush cleaners and brush replacements

– Laminating and coating brushes

A liquid catalyzed resin compound that includes pigments, dyes, and other additives is typically dispensed over the mold reinforcement. The entire mixture is then covered with an impermeable bag, while operators apply serrated hand-rollers to create a uniform distribution of resin under the bag’s surface. Manual rolling also helps ensure that the reinforcement is properly bonded with the resin, without any air pockets that may cause the molded product to degrade. This resin-reinforcement bond is crucial for effective bag molding.

Inserts and Curing

Depending on the application requirements, additional materials, such as wood or foam, may be added to the reinforcement. Likewise, metal inserts or support components may also be included, as they can be wholly incorporated within the resin-reinforcement bond. The entire unit is then transported to a different area for curing, which can be accelerated through the use of oven or infrared heating. Once cured, the solidified product is then ejected from the mold or the mold is dismantled around it. The product may then undergo further shaping or finishing treatments before being ready for use.

Bag Molding Benefits and Disadvantages

Bag molding can provide a high level of versatility in component design and lamination. Part of this is due to the precision and close thickness tolerance achievable through bag molding. Employing different types of resin compounds and reinforcements can also impart particular physical properties on the molding, allowing for a wide range of component characteristics. Bag molding also relies on relatively inexpensive material, and its tooling and machining costs tend to be low. However, the reliance on operator skill can be one of the process’s main disadvantages. Proper training and adherence to safety regulations are important, but even minor human errors can result in faulty moldings. Inspection and quality control can also be challenging, as the reliance on individual laminators and hand-rolling naturally results in small inconsistencies between production runs. Finally, the process is a relatively slow one and may require high labor costs.

PET Plastic Reclamation Processes

Share:

Reusing fabricated plastic materials, like PET plastic (polyethylene terephthalate), to make them available for further industrial processing can result in cost savings, reduced energy consumption, and lower environmental impact.

PET Plastic – Reclaimed Plastic Uses

Reclaimed plastic can be used to manufacture products such as packaging, plastic lumber, furniture, and a range of composite materials. PET is one of the most commonly recycled polymer resins, and it is used for manufacturing synthetic fibers and plastic containers, including bottles. Over a million tons of PET materials are reclaimed each year and resold to manufacturers worldwide.

Plastic recycling and reclamation services employ a number of different techniques to convert post-consumer resin into workable stock. A range of variables, such as transparency or coloring, influence the methods and intended applications for recycled PET products. The quality and yield of the plastic are also important criteria, as is the amount of peripheral material attached to the base resin. The challenge of separating non-reusable elements from the reclaimable plastic portions can alter the cost-efficiency and effectiveness of a reclamation project.

PET Granules Manufacturing Process – Sorting & Granulation

Before reclamation begins, used PET products are crushed into bales and sold to a material recovery company. The first stage in a typical PET plastic reclamation procedure involves sorting the different types of resin in order to group them together. After they have been sorted, the plastic products are ground into particles whose size depends on the particular processing method that will be used on them. These resin granules, the granulated plastic, are referred to as “flakes,” and will serve as the base forming material for future products.

Maintaining the purity of the flakes is important for preserving the reclaimed plastic’s value, as non-reusable elements can reduce workability and, ultimately, profitability. After grinding, air classification methods can be applied to filter out lighter materials, such as labels or caps, from the reclaimable plastic base. The granulation process itself helps to separate non-resin materials from the stock, but adhesives and attachments can impede the process, subsequently raising the cost of flake production by lowering total yield.

Reclaimed Plastic Cleaning

Granulated resin usually needs to be washed before it can move on to the next stage of processing. This washing can be conducted at standard environmental temperatures or at elevated heat levels. Disinfectants and detergents are often used to provide additional cleanliness. Once again, peripheral material, such as ink, linings, inserts, glue, and coatings can interfere with washing and result in a contaminated batch of resin. Ink can sometimes seep into the washing water and cause streaking, while glue remnants can cause other contaminants, such as label fragments, to adhere to the washed resin. To reduce the risk of compromised stock, recycled plastic often undergoes a second round of air classification after the washing cycle in order to remove unwanted material.

Material Separation

Plastic base resin and un-reusable materials usually have different density levels, allowing them to be separated through a hydrocyclone apparatus or a water bath. When using water, heavier resin will sink to the bottom, while lighter contaminants float to the surface. However, separating different resins from one another can be difficult, especially if they have similar density ratings. For example, a product composed of PET and PVC materials may be challenging to break down because these two materials tend to have close or overlapping densities. Products that have attachments formed from the same base resin or from a material with a significantly divergent density are therefore easier to process.

Drying and Filtering Reclaimed Plastic

After the grinding, washing, and separation are complete, reclaimed plastic is rinsed off to eliminate any remaining dirt or accumulated disinfectants from earlier stages in the process. The plastic can then be dried to prepare it for reintroduction as a manufacturing material or to undergo further treatment. Melt filtering is a fairly common post-reclamation treatment that is performed at a converter station. This filtration technique is intended to further purify the stock by removing any non-melting contaminants that may have lingered through the granulation, cleaning, and separation procedures. It uses an extruder that melts the plastic flakes and passes them through a series of screens that form the material into pellets, while blocking any non-melted particulate. Pelletizing the plastic improves the uniform quality of the stock, making it more effective for remanufacturing and, in some cases, easier to transport.