The beverage industry has witnessed a remarkable transformation over the last few decades. From the days of heavy glass bottles and aluminum cans to today’s lightweight, durable PET bottles, packaging has become more than just a container—it’s a crucial part…

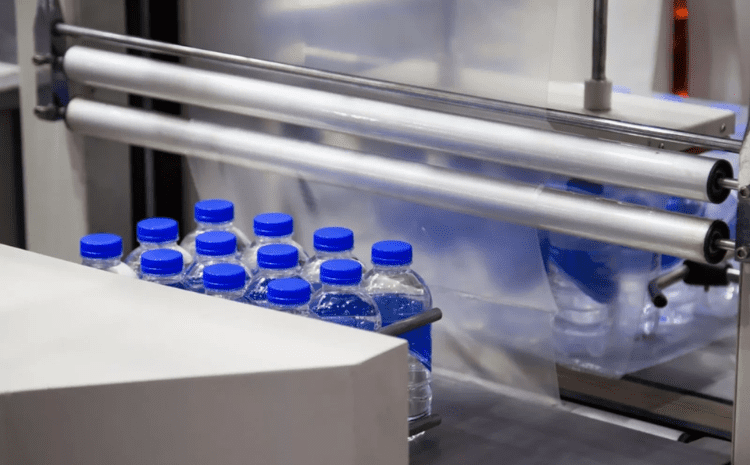

The global packaging industry is expanding at an unprecedented rate. From bottled water and carbonated drinks to cooking oil, pharmaceuticals, and cosmetics, PET (Polyethylene Terephthalate) bottles have become the packaging of choice for businesses worldwide.

The global packaging industry is expanding at an unprecedented rate. From bottled water and carbonated drinks to cooking oil, pharmaceuticals, and cosmetics, PET (Polyethylene Terephthalate) bottles have become the packaging of choice for businesses worldwide.

The bottled beverage industry is one of the fastest-growing markets worldwide. From packaged drinking water to carbonated soft drinks, the demand for hygienic, durable, and consumer-friendly packaging continues to rise

In today’s global marketplace, packaging is no longer just about containment—it’s about safety, sustainability, branding, and consumer convenience.

The beverage industry has always been one of the most competitive sectors in the global market.

The most common types of labels include shrink sleeves and pressure-sensitive labels (PSLs). Labels have become crucial for the packaging process because of the industry’s continuous advancements and the increased consumer demands for customized and visually appealing packaging.

The packaging industry has experienced significant growth and innovation in recent decades. As consumer demand for high-quality products has increased, packaging has evolved from being just a container for the product to an essential component of the user experience.

In today’s global marketplace, packaging is no longer just about containment—it’s about safety, sustainability, branding, and consumer convenience.

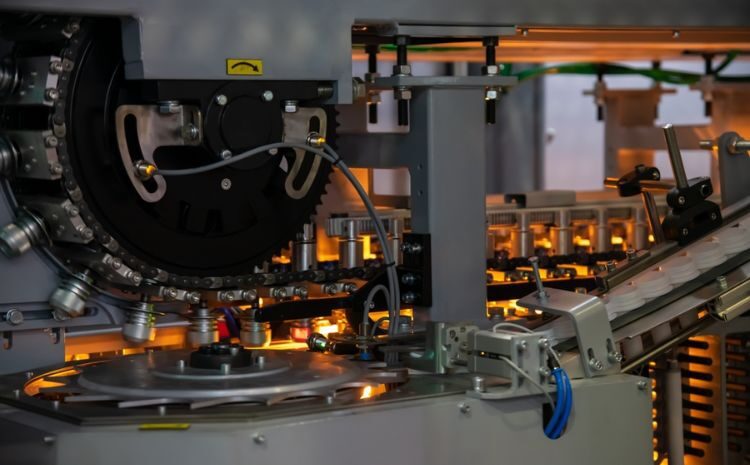

With the rapid development of industry, the requirements for equipment to improve labeling efficiency are also increasing. In order to increase production and improve output to meet market needs, various high-speed labeling systems are used.