The Need for Speed: Understanding the Advantages of High Speed Labeling Machines

In the bustling realm of modern manufacturing and packaging, speed has emerged as a paramount factor driving success. As industries across the globe engage in a relentless race to meet consumer demands, the tools they employ must not only be efficient but also incredibly swift. One such essential tool in this race is the labeling machine. Historically, labeling was a laborious manual process, but with the advent of technology, automated solutions have taken center stage. Among these, high-speed labeling machines stand out, offering industries the competitive edge they so critically need. The impetus for this shift? The undeniable importance of speed in today’s fast-paced production environments.

The Evolution of Labeling Machines

Ancient Labeling Practices:

- Early civilizations used rudimentary labels on goods, primarily for trade and storage.

Manual Labeling Era:

- As industries grew, labeling became more standardized.

- Workers hand-applied labels, leading to inconsistencies and slow production.

Introduction of Semi-Automated Machines:

- The industrial revolution saw the creation of semi-automated labeling devices.

- These machines improved accuracy but still required significant human intervention.

Rise of Fully Automated Labeling:

- Technological advancements in the 20th century brought about fully automated labeling systems.

- These machines could label thousands of products per hour with minimal human oversight.

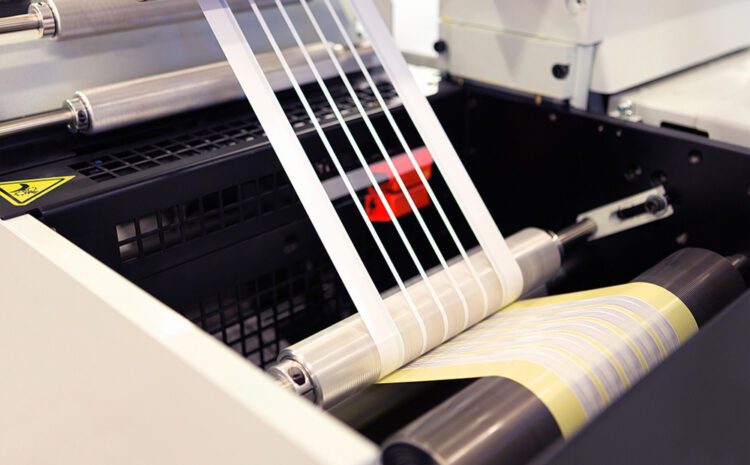

Current High-Speed Labeling Machines:

- Modern machines are capable of extreme precision at high speeds.

- Integration with digital technology ensures better tracking, accuracy, and adaptability.

Shift in Industry Preference:

- The undeniable benefits of automation have led most industries to transition from manual to automated labeling, prioritizing efficiency and consistency.

Key Features of High-Speed Labeling Machines

High-speed labeling machines are the frontrunners in modern packaging and manufacturing, ensuring products are correctly branded at impressive rates. The main features of these advanced machines include:

- Precision Label Placement: Modern sensors and software integration ensure labels are placed accurately on each product, irrespective of its shape or size.

- Rapid Throughput: These machines can label thousands of products per hour, significantly outpacing manual and semi-automated methods.

- Versatility: Capable of handling a range of label materials and adhesives, they can be adjusted for different product types.

- Integrated Quality Control: With built-in cameras and sensors, these machines can detect and reject products with incorrectly applied labels, ensuring consistent quality.

- User-Friendly Interfaces: Modern touch screen controls and intuitive software make it easy for operators to configure and monitor the labeling process.

- Robust Design and Durability: Built for industrial use, they are designed to operate consistently under strenuous conditions without frequent breakdowns.

- Energy Efficiency: Many contemporary machines prioritize lower energy consumption, reducing operational costs.

These features collectively contribute to the heightened efficiency of high-speed labeling machines. The precision ensures minimal wastage and rework, while rapid throughput accelerates production cycles. Their versatility means businesses can adapt quickly to varied product lines, and integrated quality control guarantees consistent, high-quality labeling. User-friendly designs reduce the training time and potential for human error, while durability ensures long-term, uninterrupted operations. The added benefit of energy efficiency further cements these machines as the optimal choice for modern manufacturing.

Benefits of Speed in Labeling

In today’s competitive marketplace, the swiftness with which a product moves from the assembly line to the consumer’s hands is crucial. High-speed labeling is more than just a mechanized process; it’s an essential cog in the machinery of modern business. Let’s delve into the profound benefits brought about by this rapid labeling:

Increased Production Rates: At the heart of high-speed labeling is the promise of sheer velocity. With the capability to label thousands of products per hour, manufacturers can significantly amplify their output. This speed ensures that businesses can meet large order quantities on tight deadlines, providing a competitive edge in the market.

Reduced Manpower and Human Error: Automation minimizes the need for manual intervention. With fewer hands required for the labeling process, there’s a direct reduction in labor costs. Additionally, machines, unlike humans, do not tire or become distracted. The consistency in their operation drastically reduces errors that can arise from fatigue or oversight.

Enhanced Return on Investment (ROI): While the initial investment in high-speed labeling machines might be substantial, the dividends it pays in terms of increased output and reduced operational costs lead to a quicker and more substantial ROI. Over time, businesses find that these machines more than justify their price tags.

Potential for Scalability and Adapting to High Demand: Modern businesses need to be agile. With high-speed labeling machines, scaling up production in response to surges in demand becomes seamless. This adaptability ensures that companies can cater to both regular orders and sudden, large-scale requirements without missing a beat.

In sum, the speed in labeling is not just about affixing a label quickly; it’s about efficiency, adaptability, and profitability, all of which are pivotal for businesses in the contemporary world.

Comparing High-Speed Labeling to Traditional Methods

High-speed labeling machines have revolutionized the manufacturing and packaging sectors. When juxtaposed with traditional methods, the differences are stark:

- Quantifiable Differences in Output: A high-speed labeling machine can process thousands of products per hour, whereas manual labeling methods might only manage a fraction of that. For instance, where a team of workers might label 500 products in an hour, a high-speed machine could easily handle 5,000 or more.

- Cost Efficiency Over Time: While the initial investment in high-speed labeling might be higher, the operational costs are substantially reduced in the long run. Manpower expenses decrease, errors (and thus wastages) are minimized, and production rates soar. Over a span of just a few years, the machine can pay for itself in savings and increased output.

In essence, while traditional methods have their place in niche or small-scale productions, high-speed labeling is the undeniable champion for larger, modern manufacturing needs.

Future Trends and Innovations in High-Speed Labeling

The horizon for high-speed labeling is gleaming with innovation. Upcoming technologies include:

- Artificial Intelligence (AI) Integration: AI can optimize the labeling process further by predicting and adjusting for variables in real-time.

- Sustainable Labeling Solutions: As environmental concerns grow, the industry is moving towards eco-friendly label materials and energy-efficient machines.

- IoT (Internet of Things) Collaboration: Machines that can communicate with other devices can streamline the entire production line, ensuring cohesive operations.

With these advancements, the industry is set to become even more agile, precise, and eco-conscious in the years to come.

High-speed labeling machines are the game-changers in modern manufacturing. Offering unparalleled efficiency, accuracy, and adaptability, their benefits are manifold. For businesses looking to remain competitive and future-ready, investing in these advanced machines is not just an option, but a strategic necessity. Embrace the future and reap the long-term benefits for your operations.