The Evolution of Shrink Labeling: From Sleeving to Full-Body Labeling Solutions

Shrink labeling is a popular packaging technique that involves applying a heat-sensitive film to a container, which then shrinks to conform to the shape of the product when exposed to heat. This process provides a sleek, customized appearance while also offering additional benefits such as product protection and tamper-evidence. Over the years, shrink labeling has evolved from simple sleeving solutions to advanced full-body labeling options, thanks to innovations in technology and materials. This transformation has been facilitated by the development of equipment such as fully automatic shrink wrapping machines, which have improved efficiency and precision in the labeling process. In this article, we will explore the progression of shrink labeling techniques and their growing applications.

Early Shrink Labeling Techniques

In the initial stages of shrink labeling, manual sleeving methods were predominantly used. During this process, workers would slide a pre-cut, heat-sensitive plastic film (or sleeve) onto the product container by hand. Once in place, the sleeve would be exposed to heat, typically from a heat gun or a shrink wrapping machine, causing the film to contract and conform to the shape of the container. This technique provided a relatively simple and cost-effective means of labeling products, while also offering some degree of customization and product protection.

Despite the advantages of early shrink labeling methods, they had their limitations. Manual sleeving was labor-intensive and time-consuming, making it less suitable for large-scale production. Additionally, the precision and consistency of the labels were dependent on the skill of the workers, leading to potential variations in the final appearance of the product. Furthermore, early techniques lacked the advanced design capabilities and material options available today, which limited the scope and quality of the labeling solutions. As the demand for more efficient and versatile labeling options grew, the industry began to develop new technologies and techniques to address these limitations and enhance the capabilities of shrink labeling.

Advancements in Shrink Labeling Technology

Automation

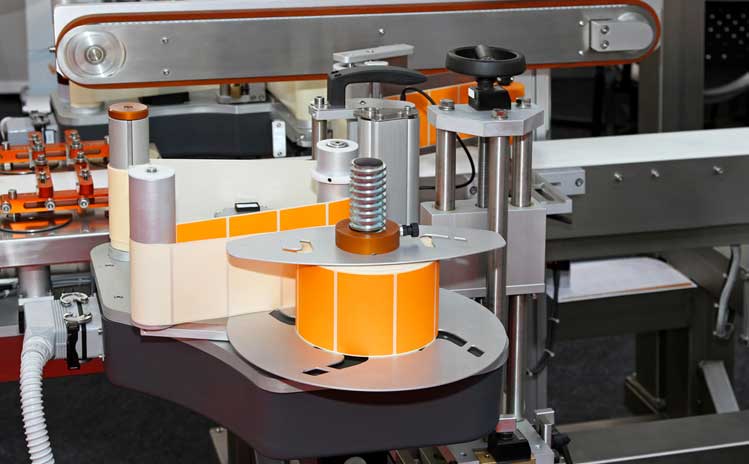

Automation has played a pivotal role in the evolution of shrink labeling. The introduction of automated machinery, such as bottle wrapping machines, has streamlined the labeling process, enabling higher efficiency and consistency compared to manual methods. These machines can accurately apply shrink sleeves or labels to containers at high speeds, reducing labor costs and production time. Automation has also increased the precision of label placement and alignment, ensuring a professional and uniform appearance across all products.

Material Innovations

Advancements in material technology have led to the development of new labeling materials, such as thinner and more durable films. These innovations have not only improved the environmental footprint of shrink labels but also enhanced their performance. Thinner films allow for better conformability to complex container shapes, while improved durability ensures that the labels remain intact throughout the product’s lifecycle. Additionally, new materials have expanded the range of applications for shrink labeling, making it suitable for a more diverse array of products and industries.

Printing and Design

Progress in printing technology has significantly impacted shrink labeling by offering higher resolution prints, a broader color spectrum, and more intricate designs. These improvements have enabled brands to create eye-catching labels that effectively communicate their identity and messaging. Furthermore, advancements in design software have facilitated the creation of customized labels with greater ease and precision. This has allowed for increased personalization, enabling companies to produce limited edition or seasonal labels as well as labels tailored to specific markets or consumer preferences. Overall, the combination of automation, material innovations, and printing and design advancements has transformed shrink labeling into a versatile and efficient labeling solution.

III. Full-Body Labeling Solutions

Benefits of Full-Body Labeling

Full-body labeling offers several advantages over traditional labeling methods. The most notable is the improved aesthetics and branding opportunities it provides. By covering the entire surface of a container, full-body labels create a seamless, 360-degree design that can enhance the visual appeal of the product. Moreover, full-body labels offer enhanced product protection and tamper-evidence, as the film covers the entire container, making it more difficult to alter or damage the product without detection.

Applications of Full-Body Labeling

Full-body labeling solutions have been adopted across various industries and for a diverse range of products. Examples include beverages, cosmetics, pharmaceuticals, and food products. These solutions are particularly well-suited for containers with complex shapes or unique designs, as the shrink film can easily conform to the container’s contours. Additionally, full-body labeling has been utilized for innovative purposes, such as multi-packs and promotional packaging, where multiple products are bundled together under a single label for special offers or limited editions.

Challenges and Considerations

When implementing full-body labeling solutions, it’s essential to consider factors such as material compatibility, label design, and equipment requirements. Shrink packaging machine manufacturers can provide guidance on selecting the appropriate machinery and materials for the specific application. Potential challenges include ensuring proper label alignment and managing material waste. However, with careful planning and collaboration with experienced suppliers, these challenges can be addressed and overcome, leading to successful full-body labeling implementations.

Throughout this article, we have traced the evolution of shrink labeling from its humble beginnings as a manual sleeving technique to the sophisticated full-body solutions available today. This transformation has been fueled by advancements in automation, material innovations, and printing and design technologies, which have expanded the capabilities and applications of shrink labeling across various industries.

As consumer demands and market trends continue to evolve, it is crucial for the labeling industry to embrace and drive further innovation. By doing so, the industry can continue to provide effective and efficient labeling solutions that meet the needs of both producers and consumers alike. Moreover, the ongoing development of new materials, printing techniques, and machinery will allow for even greater customization, sustainability, and efficiency in the labeling process.

In conclusion, the growth and progress of the shrink labeling industry are testaments to the importance of adapting to changing market dynamics and consumer preferences. By staying at the forefront of technological advancements and continually seeking innovative solutions, the labeling industry can ensure its continued relevance and success in the ever-evolving global marketplace.