Top 10 Advantages of Using a PET Blow Moulding Machine for Modern Packaging

Why PET Bottles Dominate Modern Packaging

In today’s global marketplace, packaging is no longer just about containment—it’s about safety, sustainability, branding, and consumer convenience. PET (Polyethylene Terephthalate) bottles have become the backbone of modern packaging because they are lightweight, durable, and fully recyclable. Industries ranging from bottled water and carbonated soft drinks to pharmaceuticals and cosmetics rely heavily on PET packaging to meet consumer demand.

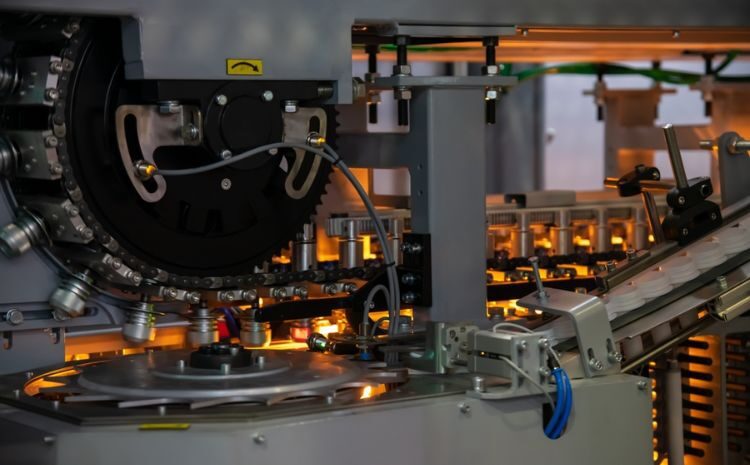

At the heart of this innovation lies the blow moulding machine. By transforming preforms into strong, reliable bottles, these machines have reshaped how businesses scale their operations. Whether it’s a PET blowing machine designed for flexibility or a high-performance automatic blowing machine built for volume, this technology offers unmatched advantages for modern manufacturers.

In this blog, we’ll explore the top 10 advantages of PET blow moulding machines and why they are essential for businesses that want to stay competitive in the ever-evolving packaging industry.

What is a Blow Moulding Machine?

A blow moulding machine is a specialized piece of equipment that uses heat, air pressure, and precision moulds to create PET bottles from preforms. Depending on the production requirements, businesses can choose between semi-automatic machines, which allow flexibility for smaller operations, and fully automatic blowing machines, which are ideal for large-scale manufacturing.

Unlike older packaging methods, PET blow moulding ensures uniformity in bottle shape, size, and quality. This is critical not only for product safety but also for brand image—consumers expect consistency, and advanced technology delivers exactly that.

1. High-Speed Production Capacity

One of the most significant benefits of a PET blowing machine is its ability to produce bottles at extremely high speeds. Depending on the model, these machines can manufacture thousands of bottles per hour. For industries like bottled water and carbonated drinks, where demand is massive and continuous, this feature is invaluable.

By investing in an automatic blowing machine, businesses can meet high-volume orders quickly, reduce delivery timelines, and capture more market share. The speed advantage directly translates into increased revenue opportunities.

2. Consistent Bottle Quality

Consistency in packaging is non-negotiable. A blow moulding machine ensures that every bottle produced meets strict quality standards in terms of shape, thickness, and durability. This uniformity is vital for companies that operate globally, where packaging compliance must adhere to international regulations.

Consistency also improves consumer trust. Whether a customer buys a water bottle in Asia, Europe, or North America, they expect the same quality and design. PET blow moulding technology guarantees this level of reliability.

3. Reduced Material Wastage

Older manufacturing processes often suffered from high material wastage due to uneven heating or inefficient moulding techniques. Modern PET blowing machines are designed to minimize waste by ensuring that preforms are heated evenly and stretched with precision.

This not only lowers raw material costs but also contributes to eco-friendly production by reducing unnecessary plastic waste. For businesses, reduced wastage means higher profitability and a stronger commitment to sustainability.

4. Flexibility in Bottle Designs

Today’s consumers demand variety—not just in beverages, but in how they are packaged. The bottle making machine provides flexibility by allowing manufacturers to produce bottles of different shapes, sizes, and designs. From small single-serve bottles to large family packs, the possibilities are nearly endless.

This flexibility also supports product diversification. A single automatic blowing machine can be adapted to produce bottles for water, soft drinks, cosmetics, and even household cleaning products, giving businesses the agility to expand into new markets.

5. Automation Benefits

Automation is transforming industries worldwide, and bottle manufacturing is no exception. An automatic blowing machine streamlines production by reducing manual labor, increasing precision, and minimizing errors. Automated systems integrate heating, stretching, blowing, and cooling into a seamless process that requires minimal operator intervention.

For large-scale manufacturers, this means reduced labor costs and higher efficiency. For smaller businesses, automation offers the ability to scale without the need for significant workforce expansion.

6. Cost-Effectiveness in the Long Run

While the initial investment in a PET blow moulding machine may seem significant, the long-term benefits far outweigh the costs. Reduced wastage, higher production speeds, lower labor expenses, and energy efficiency all contribute to cost savings over time.

Businesses that invest in automatic blowing machines often see a strong return on investment (ROI) within just a few production cycles. This makes blow moulding technology a financially sound choice for companies of all sizes.

7. Energy Efficiency

Energy consumption is one of the largest expenses in bottle production. Dunamis PET blowing machines are designed with advanced infrared heating systems and optimized cooling cycles that significantly reduce power usage.

For manufacturers, this means lower utility bills and a reduced carbon footprint. For consumers, it demonstrates a brand’s commitment to sustainability—an increasingly important factor in purchasing decisions.

8. User-Friendly Technology

Modern bottle making machines are built with operators in mind. User-friendly PLC (Programmable Logic Controller) interfaces make it easy to monitor operations, adjust settings, and troubleshoot minor issues.

This ease of use reduces training requirements for staff and minimizes production delays caused by human error. In high-pressure environments where downtime can be costly, user-friendly technology ensures continuous, smooth operations.

9. Low Maintenance Requirements

Downtime is the enemy of productivity. Fortunately, modern PET blowing machines are built with durable components and modular designs that require minimal maintenance. When servicing is necessary, maintenance can be performed quickly and efficiently, reducing production disruptions.

Low maintenance not only saves time but also lowers overall operating costs, making blow moulding machines a practical and profitable long-term investment.

10. Scalability for Growth

Perhaps the greatest advantage of a PET blow moulding machine is scalability. Businesses can start with semi-automatic systems and upgrade to automatic blowing machines as demand grows. This ensures that companies do not outgrow their machinery too quickly and can expand at a pace that aligns with market opportunities.

For multinational corporations, scalability also means the ability to replicate production lines across different regions with the same level of efficiency and quality.

Conclusion: Why Businesses Should Invest in PET Blow Moulding Machines

The advantages of PET blow moulding machines are clear: high-speed production, consistent quality, reduced wastage, flexible design capabilities, automation, cost-effectiveness, energy efficiency, user-friendliness, low maintenance, and scalability. Together, these benefits make them the cornerstone of modern packaging solutions.

At Dunamis, we specialize in providing cutting-edge PET blowing machines and automatic blowing machines that help businesses across industries meet today’s challenges while preparing for tomorrow’s opportunities. Whether you are a startup entering the bottled water market or an established multinational expanding into new beverage categories, our technology ensures that you stay competitive, efficient, and profitable.