Shrink Sleeve vs Pressure-Sensitive Labels: Machine Requirements & Use Cases

The most common types of labels include shrink sleeves and pressure-sensitive labels (PSLs). Labels have become crucial for the packaging process because of the industry’s continuous advancements and the increased consumer demands for customized and visually appealing packaging. Both shrink sleeves and pressure-sensitive labels have their own unique benefits, machinery requirements, and types of use cases where they can be applied.

The decision to use either shrink sleeve labels or pressure-sensitive labels will be based on a number of factors such as production needs, design preferences, and the intended use of the packaging. In this blog, we will be highlighting the primary differences between shrink sleeves and pressure-sensitive labels, machinery requirements, as well as the different use cases for each.

What Are Shrink Sleeve Labels?

Shrink sleeve labels are full-body labels produced using a heat sensitive material like PVC, PET or OPS. When heat is applied, they shrink closely onto the product and take the shape of the product. This provides a seamless 3D appearance and makes the product visually more appealing and improves the tamper-evidence and provides more area for brand visibility.

Machine Requirements for Shrink Sleeve Labels

Shrink Sleeve Applicators: Shrink sleeve applicators are machines that apply the sleeve to the product before it is shrunk. These machines are available for different products, including bottles, jars, cans and irregularly shaped containers. The applicators are equipped with cutting systems that trim the sleeves to the correct size and fit them to the product.

Heat Tunnels: Heat tunnels are used to shrink the sleeve once it is applied to the product. The heat tunnel uses hot air or infrared heat to activate the shrink material, which causes the label to shrink tightly around the product. The amount of heat used is controlled to ensure consistent shrinking and to prevent damage to the label or product.

What Are Pressure-Sensitive Labels (PSLs)?

Pressure-sensitive labels (PSLs) are self-adhesive labels that stick to the product’s surface and do not require heat or solvents to be applied. When pressure is applied, the label sticks to the packaging, making them extremely versatile for any product type.

PSLs are usually made of paper, film, or foil, and offer great branding and customization opportunities, including direct-printing options. Thanks to their ease of application and availability of a wide range of label materials, pressure-sensitive labels are a common choice for the industries that need speed and flexibility.

Machine Requirements for Pressure-Sensitive Labels

Pressure-sensitive labels require less complex machines for application. The machinery used for these labels is very much similar. Machines for pressure-sensitive label applicators are widely used in high-speed production lines as well as slower, more customized operations. Label applicators can accommodate rolls as well as sheets of labels.

Labeling Machines: Labeling machines are provided with a label feeder, a cutting system, and a roller system to apply these pressure-sensitive labels efficiently. Machines for these labels can be used to label bottles, cans, cartons, boxes, tubes, jars, jars, pouches, and flexible packaging.

Strength of Adhesion: Machines for pressure-sensitive labels are comparatively simple. But still, appropriate adhesion is very crucial. Label material, the surface to which it is applied, and environmental factors all play a key role in determining whether a label will adhere well to a product. This is a critical factor that manufacturers and label suppliers take into account during production and distribution.

Shrink Sleeve vs Pressure-Sensitive Labels: Key Differences

Application Process

Shrink Sleeve Labels: As their name implies, shrink sleeves are applied to a product, then shrunk with heat to form a tight seal on the container. The application process for shrink sleeves can take a bit longer (depending on the equipment involved) as it is a 2-step process and slower for high-volume production lines, but provides a high-quality full-coverage label.

Pressure-Sensitive Labels: PSLs are exactly what they sound like – you press them on! The label is applied to the container, then pressure is applied to form a seal around the edges of the label. This type of label is applied a lot faster and easier than a shrink sleeve. Plus, no heat is needed.

Label Coverage

Shrink Sleeve Labels: These labels wrap around the entire container for full-body coverage. This type of label provides a 360-degree label design that’s perfect for branding, or incorporating a security feature like tamper-evidence. Shrink sleeves are ideal for products that require a bolder or more complex look.

Pressure-Sensitive Labels: PSLs are usually applied to just the front or back of a container, rather than all around. While these labels can be just as eye-catching as a shrink sleeve, they don’t offer the same full-body coverage, and therefore design is limited when it comes to product packaging.

Durability

Shrink Sleeve Labels: Since the label fits tightly on the container, shrink sleeves are more durable and provide tamper-evidence. The shrink label becomes tightly adhered to the container so that it is more resistant to wear, scratches, or other types of damage while it is being handled or shipped.

Pressure-Sensitive Labels: While PSLs are generally sticky and adhere well, they may not be as durable, particularly in high humidity or when the product is handled roughly, putting pressure on the container and possibly the label. Modern pressure-sensitive materials have been on a steep improvement curve in terms of durability.

Machine Complexity

Shrink Sleeve Labels: As you can probably imagine, the machinery involved is more complex. Since there are two steps involved, one to apply the sleeve and another to shrink it, this process can involve a machine with an applicator and a heat tunnel. In order to shrink the sleeve, a special oven is necessary, which cannot be small or used for just one production line.

Pressure-Sensitive Labels: PSL machines are less complex than shrink sleeves and therefore more flexible. Since only one process step is required, PSL systems can be a lot faster and cost effective.

Use Cases for Shrink Sleeve Labels

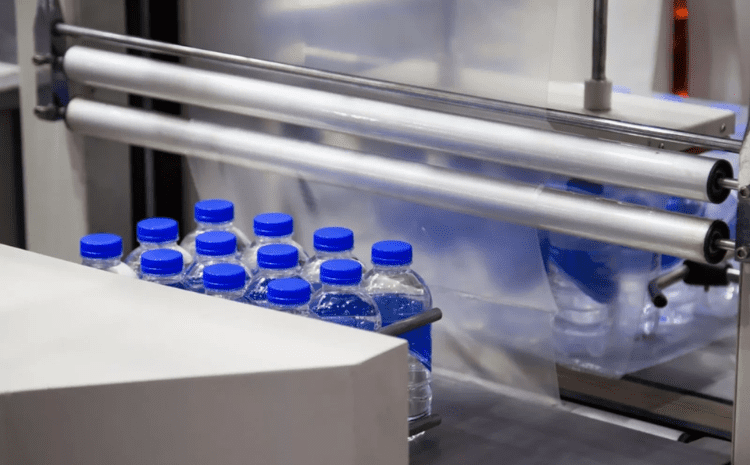

Beverages: Soft drinks, water bottles, and energy drinks benefit from shrink sleeve labels due to their tamper-evidence and ability to cover the entire bottle, including the cap.

Pharmaceuticals: Shrink sleeve labels are used for packaging medicines and health products, offering secure tamper-evident seals and clean, attractive branding.

Cosmetics: Shampoo bottles, lotions, and other cosmetic products often feature shrink sleeve labels to provide a premium appearance and full-body decoration.

Food Packaging: Sauces, spices, and other food items in plastic or glass containers use shrink sleeves for secure packaging and visibility.

Use Cases for Pressure-Sensitive Labels

Food and Beverages: Products like condiments, snack packages, and ready-to-drink beverages often use pressure-sensitive labels due to their efficiency and ease of application.

Retail Products: Cosmetics, detergents, and cleaning supplies often use PSLs for easy labeling on various shapes and sizes of containers.

Pharmaceuticals: Certain medications and OTC products are often labeled with pressure-sensitive labels, especially where small batch production is required.

Consumer Goods: For products where the aesthetic value of the packaging is important but full-body coverage isn’t necessary, PSLs are ideal.

Conclusion

We hope you can see the pros and cons in both shrink sleeve labels and pressure sensitive labels. If you need full-body coverage, tamper evidence, or durability for high-volume production, shrink sleeve labels may be the right choice. If you’re looking for high-speed production, cost-effectiveness, or easy application, pressure-sensitive labels may be the way to go.

Consider your specific needs and production line to make a more informed decision, and choose the right labeling solution that works for you. Both shrink sleeves and pressure-sensitive labels can offer high-quality and efficient labeling for your products, improving branding and enhancing the consumer experience.