BOPP Labelling Machines: Labeling Technology to the Next Generation

Businesses today face a dynamic and aggressive market and need to make sure that their packaging is fast, cost-effective, and adaptable to the new consumer needs. A new technology exploding in the labeling space is BOPP labeling machines. They are changing the labeling of any item, especially bottles, with high precision, speed and adaptability these machines offer.

Here is a complete guide about BOPP labeling machines and what they will be used for in the future of labeling, its use cases, how it works, and why businesses should consider using them for production lines.

Understanding BOPP Labeling Machines

BOPP (Biaxially Oriented Polypropylene) Label Printer Machines: BOPP label printers are used to print BOPP label on bottles, boxes, etc. These machines are fitted with a high-tech that allows for fast and accurate labelling and they are ideal for high volume productions.

BOPP labels are a polypropylene film that has been machine- and transversely stretched for increased resistance, transparency and adhesion. These films are used by BOPP labeling machines to print ultra-durable and attractive labels for various containers.

Why Choose BOPP Labeling Machines?

BOPP labeling machines, mainly because of the need of advanced packaging technology, is the most preferred solution for businesses across industries. The advantages of BOPP labelling machines as labelling technology: Here are just some of them:

- High-Speed Efficiency

This is one of the major features that BOPP labeling machines has, which can work fast. There are several manufacturing sectors like Food and beverage, pharma, consumer goods etc where a high-speed labelling machine is needed. Such machines can mark thousands of bottles an hour, so you don’t miss any steps on your production line.

• Whether it’s a rotary labeler or an automatic labeler, BOPP labeling machines have the high speed to support steady production and lower downtime for manufacturers.

Cost-Effective Labeling Solution

BOPP labelling machines are a good value for money because they make the most out of your production line. Automatic labelers save time and labor since they can put labels on faster than a human hands. Also, BOPP labels are extremely durable and tear resistant which ensures that they can be stored for longer and need to replace more often.

• BOPP labeling machine cost is affordable as compared to other labeling technologies. Optimal savings on the business side from a BOPP labeling machine are well worth the upfront investment over the long term.- High-Quality Labeling

One of the primary driver for product appeal and branding is the label quality. BOPP labels are clear, sharp, and printable which will make your labels visible on the shelf. Whether it is water bottle labels, soda bottle labels or cosmetic label labels, BOPP labeling machines make the labels come out crisp and wrinkle-free, which gives your product an attractive look.

• BOPP label printing machines can also produce complicated label designs, businesses can print BOPP label printing machines for the complex, colorful and detailed designs to promote brand image. - Versatility in Application

Another excellent aspect of BOPP labeling machines is flexibility. The machines can label bottles, jars, cans, etc. That’s why they are appropriate for all sorts of sectors, including:

• Water bottle labeling machine: BOPP labelling machines adhere very well to water bottles, and the label integrity is guaranteed even in the conditions of storage.

• CSD Bottle labeling machine for CSD (Carbonated Soft Drinks): BOPP labelling machines have a flexible structure, so it is ideal for carbonated beverage bottles whose labels must not easily tear from high pressure from the carbonation.

• Automatic labeling machine: On more-sized production lines, automatic labeling machines print BOPP labels for all products on a high-speed. - Customization and Branding

BOPP labeling machines are the most flexible label makers in the world. So if you need to print barcodes, product information or graphics, BOPP labelling machines are up to the job. Some BOPP labeling machine manufacturers also manufacture the machines that can be integrated with printed materials, so you can put logos, branding designs and more on the labels directly.

• BOPP labels also adhere to a product very well and do not tear even when in harsh environmental environments making the label readable and attractive for the shelf life of the product.

Reduced Downtime

A concern of every manufacturer is how to reduce downtime and run continuous production. Automated BOPP labeling machine prevents errors and mechanical malfunctions and makes operation easy. The modern characteristics of these machines — automatic tuning and diagnostics, for instance — make sure the machine is operating efficiently.

• Automatic labeling machines automatically pick up the problem and solve it before it messes up the labeling, saving labor costs and stopping production.

How BOPP Labeling Machines Work

To know the working of BOPP labeling machines is imperative for the businesses to avail this technology. A quick primer on the workings of these machines:

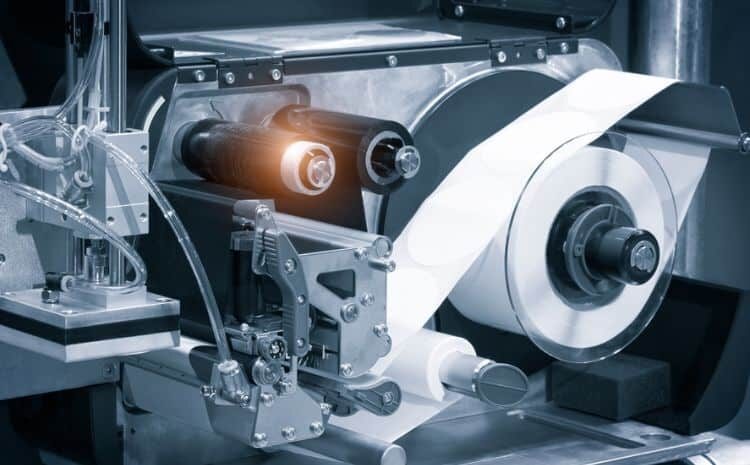

1. Label Unwinding: The BOPP label stock which is in a roll is unrolled by the machine. The label roll goes into the labeling unit which feeds it through a set of rollers.

2. Application of Label: As bottles or containers slide along the belt conveyor, BOPP label is applied by the bottle of the labeling machine on the container. The label is applied correctly at the right location with the right tension on the machine through a mechanical process.

3. Stickiness: The labels are glued to the containers using pressure sensitive adhesives, hot glue, or any other adhesive depending on the kind of automatic label machine used. BOPP Labeling machines are very effective for labeling with Glue Label Machine because it’s long lasting.

4. Finishing: Once applied, the bottle goes through a row of rollers that adhere the label to the container with no wrinkles or bubbles.

BOPP Labelling Machine Application In Industry: BOPP Labeling Machines Application in various Industry.

- Beverage Industry

BOPP labeling machines are the best solution when it comes to beverages labeling machine like water bottle labeling machine. They let manufacturers mark bottles with pinpoint precision so that every bottle is clearly labelled. BOPP labels are extremely hard-to-remove and adhere to a great deal which is important when it comes to the cold wet environments that we see commonly in beverage packaging.

2. Cosmetics Industry

BOPP Labelling Machine: The beauty industry can use BOPP labeling machines because they can create good-looking labels. Whether shampoo bottles or cosmetics, BOPP labelling machines help you put the labels on with minimal mess, even in distorted bottles.

3. Pharmaceutical Industry

For pharmaceutical companies, accuracy and security matter most. BOPP label printers make labels are applied in the correct way and consistent on the pharmaceutical bottles and packaging conforming to all regulations. BOPP labels are both clear and resistant which preserves important data like the dosage, expiration date, and product information.

BOPP Labeling Machines Future the BOPP Labelling Machines Future.

As demand grows and production demands evolve, the BOPP labeling machine’s future is extremely bright. Automation, connectivity, machine learning and so on will make the next generation of BOPP labeling machines faster, more efficient and more accurate.

Smart Labeling: The AI and IoT – enabled automatic labeling devices will become more smart and can adjust their functionality on the basis of real-time feedback and proactive maintenance information.

Sustainability: Machines manufacturers are constantly striving to make labels more efficient, so they do not throw away or use materials which are in keeping with the world’s trend towards saving resources.

Conclusion

BOPP labeling machines are changing how companies think about product labeling as it is faster, efficient and cost-effective. These are fast, precise, versatile, and able to provide good labels — the keys to cutting-edge lines.

Companies can reduce time, cut costs and improve their packaging with BOPP labelling machines and gain brand awareness and satisfaction from consumers. As the labeling technology trends change, BOPP labeling machines will never go out of style and provide businesses with a solid, sophisticated solution to meet the growing needs of today’s marketplace.