The Importance of Blow Molding Machines: Revolutionizing Manufacturing

In the realm of modern manufacturing, efficiency, precision, and versatility reign supreme. Among the myriad of technologies that drive this evolution, blow molding machines stand out as indispensable tools that have transformed the production landscape across various industries. From packaging to automotive components, blow molding machines play a pivotal role in shaping everyday products. Let’s delve into the significance of these machines and how they have become indispensable in today’s manufacturing processes.

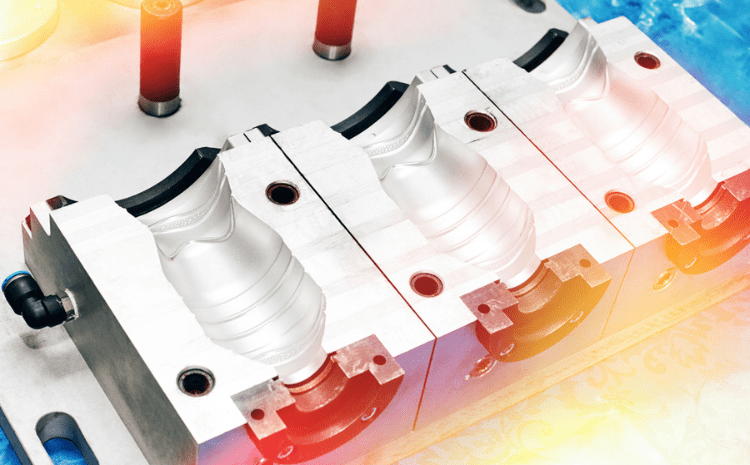

Understanding Blow Molding Machines

Blow molding is a manufacturing process used to create hollow objects by inflating a heated plastic tube (referred to as a parison) until it takes the shape of a mold cavity. The process encompasses various techniques, including extrusion blow molding, injection blow molding, and stretch blow molding. Each technique caters to specific product requirements, ranging from simple containers to complex automotive parts.

The Versatility of Blow Molding

One of the primary reasons for the widespread adoption of blow molding machines is their versatility. These machines can produce a diverse range of products with varying shapes, sizes, and complexities. Whether it’s bottles, containers, drums, or automotive components, blow molding machines can accommodate a wide array of designs, making them ideal for manufacturers seeking flexibility in their production processes.

Cost-Effectiveness and Efficiency

Blow molding machines offer significant cost advantages compared to traditional manufacturing methods. By utilizing materials efficiently and minimizing waste, these machines help manufacturers reduce production costs without compromising quality. Additionally, the high-speed capabilities of modern blow molding machines enable mass production, further enhancing cost-effectiveness and overall efficiency.

Customization and Design Freedom

In today’s consumer-driven market, customization is key to staying competitive. Blow molding machines empower manufacturers to meet evolving consumer demands by offering extensive design freedom. With advanced software and mold-making technologies, manufacturers can create custom molds tailored to specific product requirements. This level of customization not only enhances product aesthetics but also allows for innovative designs that differentiate brands in the market.

Sustainability and Environmental Impact

As sustainability becomes a focal point in manufacturing, blow molding machines play a crucial role in reducing environmental impact. By utilizing recyclable materials such as PET (polyethylene terephthalate) and HDPE (high-density polyethylene), manufacturers can produce eco-friendly products that align with sustainability goals. Moreover, the energy-efficient operation of modern blow molding machines minimizes carbon emissions, further contributing to a greener manufacturing ecosystem.

Quality Assurance and Consistency

Quality control is paramount in manufacturing, and blow molding machines offer unparalleled precision and consistency in product manufacturing. From maintaining uniform wall thickness to ensuring dimensional accuracy, these machines uphold stringent quality standards throughout the production process. As a result, manufacturers can deliver high-quality products that meet customer expectations while minimizing defects and returns.

Applications Across Industries

The versatility of blow molding machines extends across various industries, driving innovation and efficiency in product manufacturing. In the packaging industry, these machines are instrumental in producing bottles, containers, and packaging solutions for food, beverages, pharmaceuticals, and personal care products. In the automotive sector, blow molding machines manufacture components such as fuel tanks, air ducts, and interior trim parts with exceptional strength and durability. Additionally, blow molding technology finds applications in industries such as aerospace, electronics, and consumer goods, further underscoring its significance in modern manufacturing.

Automation and Industry 4.0 Integration

The integration of blow molding machines with automation and Industry 4.0 technologies has further enhanced their importance in modern manufacturing. Automated blow molding systems leverage robotics, sensors, and advanced control systems to streamline production processes and optimize efficiency. With automated material handling, mold changing, and quality inspection, manufacturers can achieve higher throughput, reduced downtime, and improved product consistency. Moreover, connectivity features enable real-time monitoring and remote control, empowering manufacturers to make data-driven decisions and optimize production in response to changing demand. By embracing Industry 4.0 principles, blow molding machines are at the forefront of the digital transformation in manufacturing, driving increased productivity, flexibility, and competitiveness.

Innovation and Future Prospects

The relentless pursuit of innovation continues to propel the evolution of blow molding machines, opening up new possibilities and applications. Advancements in materials, mold design, and process technologies are expanding the capabilities of blow molding, enabling the production of lighter, stronger, and more complex products. For example, developments in multi-layer extrusion technology allow for the creation of barrier packaging with enhanced shelf life and product protection. Similarly, advancements in blow molding simulation software enable virtual prototyping and optimization, reducing time-to-market and development costs. Looking ahead, the future prospects of blow molding machines are promising, with ongoing research and development focusing on areas such as sustainable materials, additive manufacturing integration, and digital twin technologies. As manufacturers embrace these innovations, blow molding machines will continue to play a pivotal role in shaping the future of manufacturing, driving efficiency, sustainability, and innovation across industries.

Supply Chain Resilience and Localized Manufacturing

In recent years, the importance of supply chain resilience has become increasingly evident, driven by global disruptions such as natural disasters, geopolitical tensions, and the COVID-19 pandemic. Blow molding machines contribute to supply chain resilience by enabling localized manufacturing and reducing dependency on distant suppliers. By establishing production facilities closer to consumer markets, manufacturers can mitigate risks associated with transportation delays, geopolitical instability, and supply chain disruptions. Furthermore, localized manufacturing facilitates just-in-time production, reduces inventory costs, and enables faster response to market demand fluctuations. Blow molding machines play a crucial role in this paradigm shift towards decentralized production, empowering manufacturers to build resilient supply chains that are agile, adaptable, and capable of weathering unforeseen challenges. As businesses prioritize supply chain resilience in a volatile global landscape, the importance of blow molding machines in enabling localized manufacturing will continue to grow, fostering greater stability and sustainability in the manufacturing ecosystem.

Conclusion

In conclusion, blow molding machines have emerged as indispensable tools that revolutionize manufacturing across industries. Their versatility, cost-effectiveness, customization capabilities, and environmental sustainability make them invaluable assets for manufacturers seeking to stay competitive in today’s dynamic market. As technology continues to advance, the importance of blow molding machines will only grow, driving innovation and efficiency in product manufacturing for years to come.