Is an Impact Molding Maker Used to Make Anything Other than Plastic Containers?

For producing plastic containers, professionals rely upon a modern strike molding machine. With this specific procedure, a maker produces a wide series of completed items in differing shapes and sizes. As a result of that, several ind

ustries rely on a professional firm to make a specific type of plastic bottle needed.

However, a leading manufacturer makes use of a blow molding equipment for producing a great deal more than simply plastic bottles. Although that is the primary function, blow molding equipment is ideal for various other items. With different kinds of plastics readily available for this procedure, an experienced supplier can offer all sort of companies with conventional as well as personalized requests.

Plastic for Impact Molding Machinery

Complying with are some examples of the most effective plastics made use of with an impact molding maker. Bear in mind that because each has special residential properties, it is imperative the customer collaborate with a manufacturer with substantial expertise of the various options offered, thus selecting the appropriate plastic for the product.

High-density Polyethylene (HDPE) Of all the materials utilized with impact molding equipment, this is the most common. Made use of to produce bottles for different applications, not just is HDPE durable yet also one of the safest plastics readily available.

Polyethylene Terephthalate (ANIMAL) As a sort of polyester, firms utilize pet dog to make clear containers.

Polypropylene (PP)s one more preferred plastic, PP has superb tightness and low-density, making it ideal for high-temperature applications. Although clear, a manufacturer can tint it.

Polycarbonate (COMPUTER) As a clear and solid material, computer works terrific for generating plastic bottles, especially those with complicated shapes.

Reaching Beyond Plastic Bottles

On a daily basis, you either see or take care of plastic bottles used for points like water, soft drink, cleansing items, and more. Nevertheless, impact molding equipment can create much more than just containers. Making use of the same materials listed, plus a few additional, a producer has the capabilities to generate items for all kinds of industries and applications. Right here are 2 instances:

HDPE– With this plastic, manufacturers create containers for antifreeze, electric motor oil, and hair shampoo. Nevertheless, HDPW is also the product of option for generating industrial drums, gas tanks, and other larger items.

COMPUTER– This material makes an excellent choice for anything that needs extreme strength, consisting of bulletproof glass. Nonetheless, producers additionally utilize it to make 5-gallon water containers and also eyeglasses.

With an impact molding equipment, a business can make plastic specimen containers and also tubing used by the clinical market, sprinkling containers for serious garden enthusiasts, containers that hold soup, peanut butter, and a selection of various other foods, and also makeup situations and also containers for the cosmetics sector, amongst several others.

Choosing a Trusted Impact Molding Device Supplier

For your company to create stellar items that fulfill stringent requirements, you require state-of-the-art equipment. That indicates looking to a skilled strike molding machine maker like PET All Manufacturing. We offer our clients with only one of the most advanced equipments offered. Whether you need to produce containers or a few other sort of plastic item, you can depend on us to deliver superb equipment.

Can Extrusion Blow Molding Create Complicated Shapes?

When it pertains to extrusion impact molding capability, most individuals consider common plastic bottles, tight-head containers, jars, and also bigger water containers. Nevertheless, the extrusion strike molding procedure can do a lot more. As a matter of fact, when utilizing a technically sophisticated extrusion impact molding device, it can produce finished products with complicated forms, and in differing dimensions.

Understanding the Extrusion Impact Molding Refine

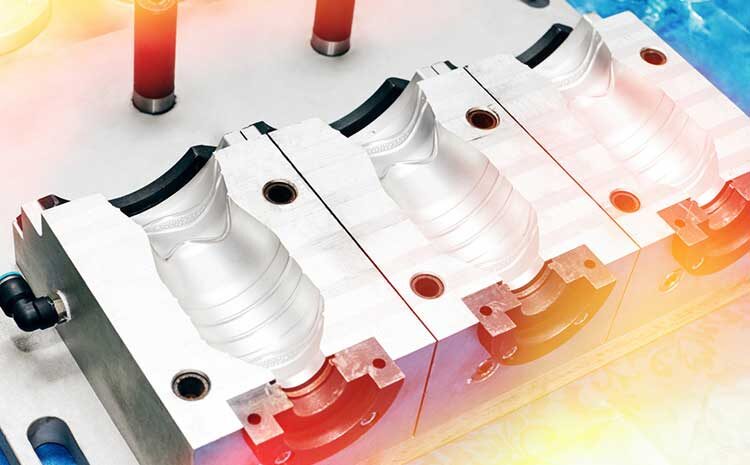

Whether you need a traditional designed product made or something with a complicated design, the procedure for extrusion strike molding continues to be relatively the same. The only actual distinction is the mold and mildew. With this, resin goes into a hopper installed on the top of the device. It then moves along the track that overviews it to the barrel. As the material gets closer, an internal revolving screw pressures it inside the heated barrel.

With melted plastic, the extrusion strike molding equipment can operate properly. With regulated warm zones inside the barrel, the temperature increases gradually. As the plastic thaws, it takes a trip with the barrel, pushing with a screen that strains any impurities. Next, the melted resin fills the mold and mildew, which offers the final product its form. When cooled, the product ejects from the mold.

Particularly for accomplishing challenging shapes, it is necessary that you rely on a remarkable high quality equipment for extrusion blow molding. The factor is that unless the dissolved resin flows into the mold equally or if some other problem takes place, you could anticipate to see a warped and also unusable product. Fortunately, the ideal equipment makes sure a smooth extrusion strike molding process that generates impressive ended up items.

While you anticipate this equipment to generate water and also soda bottles, jars for numerous foodstuff, containers for auto oil, and more, it can additionally produce all kinds of more difficult forms. As an excellent example, in place of metal gas storage tanks, the majority of car manufacturers now count on plastic. Although a big yet likewise distinctively shaped product, the extrusion blow molding process is suitable. This process is likewise excellent for making plastic child seat, mannequins, and also a wide range of other items with complex forms.

Resort to the most effective

For both standard and intricate plastic forms, you need to work with a cutting edge extrusion impact molding maker. With that, you have the guarantee of accomplishing a stellar end product. At pet dog All Manufacturing, a leader in making excellent machinery, we have an option for your particular needs. Every equipment we market boasts special features like high-impact resistance, controlled wall surface density, light-weight yet long lasting, adaptable part design, and also environmental resistance.

Why go for second best when you can look to us for the best. Among our representatives will patiently answer your concerns as well as give information to help you make an all-important choice.